S S T C 2

A Weekend Solid State Tesla Coil

& my guide to How to

Build a SSTC! |

How to build a Solid State Tesla Coil

If you are here to learn how to build a SSTC, you have come to the

right place! Welcome!

The design and construction a Solid State Tesla Coil (a Tesla Coil

powered by Transistors instead of a spark gap) is not a trivial task.

However, the basic mechanism and workings of a SSTC are not too

complicated. The main challenge in building a SSTC lies with

the fact that the builder should have a good understanding & experience with electronics,

and have some test equipment (oscilloscope is required) for

debugging, which many beginners may not have. There are also several subtle but important things to take note of

which are usually difficult to find information about.

Unlike spark-gap or vacuum tube Tesla Coils, building an SSTC is not as straightforward as copying a

schematic. When I began building SSTCs a few years years ago, I found it

difficult to find information on how to build one, and what to look out

for.

Most tesla-coilers, through their own coiling successes and

mistakes, have developed an intuitive understanding of the nuances of SSTC

construction, and perhaps found them not worthy of specific mention.

This has led to the motivation to write this page - a basic practical guide to

Solid State Tesla Coils. I hope to write a useful and concise

document aimed at the budding coiler who has perhaps built a Spark Gap

Tesla Coil before, and wishes to move on to transistor Tesla Coils.

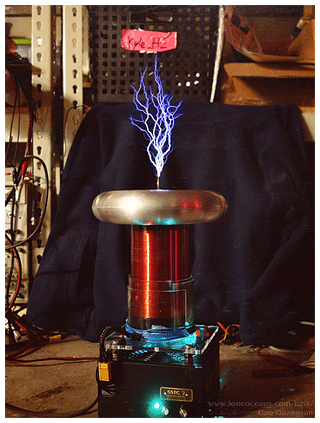

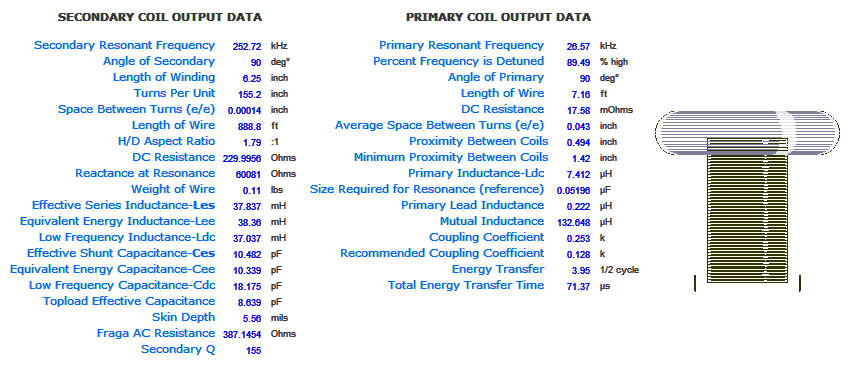

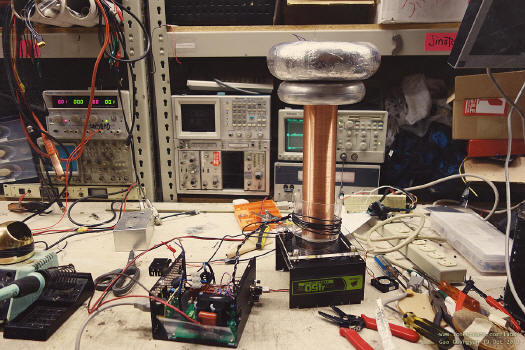

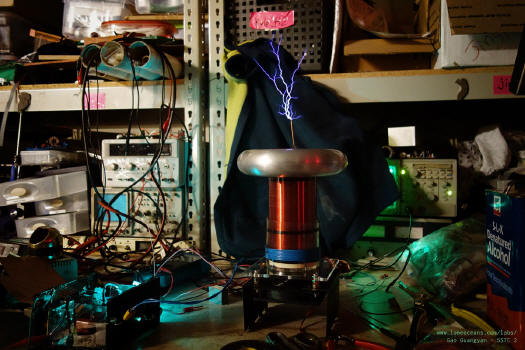

I will document this guide through the construction of a very simple Solid

State Tesla Coil - SSTC 2 - which I have designed to be simple, compact, and produces

good results. I will try to explain some of my design choices. Also, I wanted to see what I was able to cook up in a

one busy weekend in school! The result is the photo shown on the right

(and actually took 2 weekends to complete.. but that's not too bad I

hope!)

You might also be interested in my previous Spark Gap Tesla Coils,

Tesla Coil 1 and

Tesla Coil 2.

Also, check out my first SSTC 1, along with my

newer DRSSTC 1, DRSSTC

2 and DRSSTC 3 coils - a more powerful variant of the SSTC.

Thanks for

visiting my page and if you have any questions, wish to share your

projects, or feel that my projects have inspired you in one way or

another, feel free to email me at loneoceans[at]gmail(dot)com. I'd love

to hear about your projects too. Additionally, if you find any mistakes

in my write up, feel free to drop me a note! If this page was helpful,

feel free to share it with others too!

I would appreciate any credit if you choose to use any

of the design / code for your own projects. Good luck! Finally, I would

like to thank the very many people especially Steve Ward, Bayley and

Phillip whom I had very many conversations with and helped me in writing

this guide.

Page Contents

1. Introduction

2. Components of a SSTC

3. Construction of a Weekend Coil

4. Results and Media

5. Credits and Links

SSTC 2 Final Specifications (05 Nov 2013)

- 120VAC input (+-170 across primary)

- 249kHz Resonant Frequency

- Half Bridge of Fairchild HGTG30N60A4D IGBTs

- 3.5" x 6.25" secondary with 34 AWG (~975 turns)

- 4.56 x 0.65" 6 turn primary with 14 AWG

- Secondary current feedback (50:1 ferrite transformer)

- 8" x 1.9" stamped aluminium toroid

- Interrupter - 0 to 1500us, 1 to 254Hz via ATtiny85

- Spark Length to air ~9" (22.5cm) (05 Nov 2013)

For much more videos and images of the coil in action, please scroll down to

Results!

10 Oct 2013

Introduction

Before I begin, it is good to have a basic understanding

of how a Tesla Coil works. For that matter,

Wikipedia provides

a good narrative and overview. Also, caveat - if any of you more

experienced coilers out there finds some mistake in my write up, feel

free to notify me for me to fix it! :) Finally, if you are a serious

hobbyist who doesn't have an oscilloscope, I would say it is mandatory

to buy yourself a scope for you to really grow as an engineer! You can

pick an old analog one up cheap for less than $100 these days, and you

will really need it for debugging your SSTC.

Tesla Coils

A Tesla Coil is an air-cored resonant transformer

capable of generating extremely high voltages. Its construction is

relatively straightforward, but the theory is a bit more involved. The

key concept of a Tesla Coil is its resonant property, where a

Resistor-Inductor-Capacitor (RLC) resonant circuit is energized at its

resonant frequency, developing very high voltages.

A Tesla Coil consists of two concentric coils which are

not electrically connected to each other. The Primary Coil usually

consists of a few turns of heavy wire, and has a shape ranging from a

solenoid to a flat spiral. This coil is usually connected to some

capacitor, forming the Primary LC circuit (if you are unfamiliar with

RLC circuits, feel free to browse Wikipedia for a quick introduction).

The secondary circuit consists of a long coil of wire, usually having

several hundreds to thousands of turns wound on a pipe, and placed

concentrically in the middle of the coil.

Game plan: For a

normal SSTC, we will focus on creating some sort of circuit

to energize

the secondary coil at its resonant frequency.

* Note that SSTC operation

differs slightly from Spark Gap Tesla Coils or the newer Double Resonant

Solid State Tesla Coils, where the primary circuit is also oscillating

at a resonant frequency similar to the secondary coil. In a conventional

SSTC, the primary circuit is not resonant. *

How does a SSTC work?

Simply put, a normal Solid State Tesla Coil (SSTC) is simply a power

amplifier driving a primary coil at the resonant frequency of the

secondary coil. As mentioned, the secondary circuit is a coil of wire,

one end of which is grounded, and the other end is connected to some kind

of topload (metallic volume) at the top of the tube. This topload is usually in the shape

of a toroid (looks like a doughnut). The toroid provides some sort of

capacitance to the secondary, its shape serves well in

electric field control, and also looks cool! However, other shapes such

as spheres are also common. This topload capacitance (usually small, on

the order of pF - can be calculated) and secondary coil in series form

an L (inductor) C (Capacitor) circuit with a resonant frequency

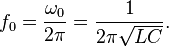

described by:

The ratio of L and C also determines the Q-factor of the

system (which affects the selectivity, or how narrow its resonant peak

is). Think about the resonant frequency as if the circuit was like a

swing, which naturally wants to swing at a certain rate. Our goal is

then to find a way to drive this primary coil at the secondary's

resonant frequency.

The way we achieve this is by switching power into the

primary coil at the resonant frequency of the secondary. We do this by

creating

a high-voltage square wave across the primary coil using an

inverter circuit. This circuit comes in two common forms - a half bridge or a full

bridge. Line voltage (120 or 240VAC depending where you live) is

rectified and stored in a large bus capacitor (several hundred to

thousands of uF), and the inverter works to create an AC square wave

across the primary. The result of this is a sinusoidal current in

the primary coil due to it being driving at resonance.

Next, we need to know what the resonant

frequency is. To determine the correct frequency to drive the coil, an

external oscillator can be used (requires tuning), or feedback can be

taken from the secondary or primary coil for self-oscillation.

*note* A DRSSTC differs from this with the addition of a

primary tank capacitor in series with the primary coil. The goal

here instead is to not only drive the secondary at resonance, but to also drive

the primary at the same resonant frequency. Now, as the inverter

switches the primary, the current is still sinusoidal, but grows.

Additionally, due to resonance, the primary voltage also increases from

line voltage up to the several kV. This gives the primary a better

impedance match to secondary circuit. The current also increases up to

several hundred (to thousands) Amperes. Due to this second resonance,

this variant of SSTCs are known as Double Resonant SSTCs. The

result is much larger sparks in the output!

When the secondary coil is driven at resonance, a large

voltage develops across the coil. Using an example of a swing, if we keep

supplying 'pushes' at the correct resonant frequency, the swing gets

higher and higher. Similarly, a large voltage develops on the top load,

eventually leading to electrical ionization and breakdown of the air,

forming sparks.

With a basic understanding of how an SSTC works, lets

see how we can get all the parts working together.

Parts of a SSTC

Let us break down the SSTC into is fundamental

building blocks. The are three main parts to the system.

-

The

first is the low-voltage logic control and gate driver.

This part creates the signals to drive our inverter (half or

full bridge). In this circuit, we find a way to generate the

correct frequency either via feedback or by an external

oscillator, and then create appropriate signals to drive our

transistors in the inverter.

-

The second is the high mains-voltage inverter

itself,

which drives the primary coil. This circuit handles the big

currents, and also consists of our rectification system (from

mains to a big capacitor), as well as a set of large power

transistors. MOSFETs have been used in SSTCs, but IGBTs have

become popular choices.

-

The last circuit is the

secondary coil which basically consists of only the coil and

the topload, and is electrically isolated from the previous two

circuits.

-

Driving the SSTC in continuous mode consumes large amounts of power and heats up the

transistors

significantly. Hence, SSTCs these days often come with an

interrupter, which is basically a small controller which

turns the gate driver on and off. This

allows the user to control the duty cycle of the SSTC. The

interrupter controls the pulse-width, which is the

duration the inverter is turned on (usually from 10 to 300us in

DRSSTCs, and up to several ms in SSTCs), and the

breaks-per-second.

We will examine these parts in detail in

the next section.

Making Music with the SSTC

With the interrupter, we can now create a

variety of modes to drive the SSTC! For example, I could set my

interrupter to turn the tesla coil on at 200 Hz with about 10%

duty cycle. This means we turn the tesla coil on for 500us, 200

times a second. Each pulse makes a spark and an associated 'bzzt'

sound. If we make this sound 200 times a second, we end up with

a note at 200Hz (albeit a rather harsh one). We can vary this

frequency and produce different notes (you can think of this

like FM)! This is the basis for most musical Tesla Coils today.

The second method is more involved and will not

be discussed further here. But the basic principle is to run the

SSTC in continuous-wave mode (no interrupter, so it is on all

the time), but modulate the input voltage to the inverter with

the envelope of the music (think of this as AM)! This allows a

greater fidelity in output power. Consequently the spark that is

created grows and contracts based on the input power, creating

air pressure waves which are heard as music.

Components of a Solid State Tesla Coil

Let us now discuss in more detail the basic

building blocks of a SSTC. I will explain these through the

design of an actual SSTC. Before I build the

coil, lets think about the design a bit more first:

Power Inverter

The goal of the inverter is to produce a square

AC wave across the primary coil.

Bus Supply

The bus supply as it is named, supplies the

power to the input of the inverter. This is usually rectified

mains AC, which can simply be stored in a large electrolytic

capacitor. During switching, the inverter pulls power from this

capacitor (several tens to hundreds of Amperes for the short

duration of the on-time), which is driven into the primary coil.

The capacitor is important to supply this large current draw. In

addition, we do not wish for the voltage to drop too much during

the on-pulse, hence we want a large capacitor. Typical values

begin at around 1000uF. A few hundred uF works fine for small

coils.

As I am currently in the United States, I have

to work with 120VAC line voltage. After rectification, this is

just about 170VDC, which would give me +-85V in half-bridge

configuration. However, running the primary at higher

voltages produces bigger sparks! To increase the voltage supplied to my

bus, I have used a simple voltage doubler circuit, which

essentially produces 120V * 2 * (Sqrt 2) volts DC (about

340VDC). This is supplied to two 250V 1000uF capacitors (in

series), providing a bus capacitance of 500uF at 500V (charged

to 340VDC). Do not forget to add bleeder resistors across the capacitors to

make the device safer! 100k resistors should do the trick.

Configuration

There are two possible layouts for the inverter

- a half bridge or a full bridge.

The main advantage of the half bridge is

simplicity and lower part count. However, the advantage of a

full bridge is twice as much voltage across the primary and

hence most possible power. In this coil, a half bridge has been

chosen for ease and compactness, but this can be easily extended

to a full-bridge. Since I have a voltage doubler making my bus

340VDC, my primary coil sees +-170V across.

One important thing to note in the physical

design of the bridge is to minimize stray inductance.

This is done by keeping any leads or wires physically as close

together as possible. Because large currents will be flowing in

our bridge, the switching can induce large voltage spikes if our

inductance is too large. To solve this problem, I have used a

PCB with a laminated bus structure for my half-bridge. Check out

my SSTC 1 for how I did it using wires

instead.

Keep your bus capacitor as close to the transistors as possible,

and make sure that the transistors are mounted on a heat-sink.

Additional things to take note of include adding

subber capacitors to the IGBTs (film capacitors mounted

physically close to the IGBT - these are meant to soak up

transient high voltage spikes and thus are usually rated around

1kV and 1 to 6uF - I have omitted them in my design because of

the low-inductance layout of my bridge. Also, adding Transient

Voltage Suppressors across the CE of the IGBT (or DS of the

MOSFET) - usually bidrectional TVS of the 1.5KE220 type are used

(series if required), and minimizing bus inductance as much

as possible to reduce voltage spikes. Running the transistors no

more than 2/3 of their specific voltage rating is good practice

also.

Transistor Selection

SSTCs have traditionally been powered by MOSFETs

(metal oxide semiconductor field-effect transistor) instead of

the more common bipolar transistor. In a normal bipolar

transistor, a small base current is used to drive a large

emitter-collector current. In this way, BJTs are

current-operated devices. However, in a SSTC operation where we

may be switching significant currents (several tens to a hundred

Amps) at high frequencies, we will need large currents (on the

order of several 0.1 to 1A) to switch our transistor, making

this very challenging.

A MOSFET is a voltage-operated device, where a

small gate voltage switches a large drain-source current. They

are very nice as switches due to their high off-resistance, low

on-resistance and only require a small gate current to turn-on

(basically charging up a small capacitor in the gate to turn it

on). Their fast switching speed is ideal for SSTCs. However,

MOSFETs are more sensitive to static, and more expensive.

In recent years, the demand for power

electronics (e.g. inverter applications like electric vehicles)

has seen the rise of a newer type of transistor, the Insulated

Gate Bipolar Transistor (IGBT), which combines the simple

gate-drive characteristics of MOSFETs with the high-current and

low-saturation voltage of a BJT. Additionally, the MOSFET

voltage drop is like a resistor, hence power dissipated goes up

with I^2R - significant in high current switching. However, the

IGBT has a constant voltage drop like a diode (actually

increasing with the log of the current), the the power

dissipated is more like IV, significantly less. Hence, while

MOSFETs are good for high frequency low current switching, IGBTs

are better for lower frequency and high current switching,

making them popular choices in the Tesla Coil community.

This design should work with standard MOSFETs

such as the IRFP260 (200V 46A), IRFP460 (500V 20A), or FCA47N60

(600V 47A). The use of these requires fast free-wheeling diodes

in parallel to conduct current in the opposite direction. These

free-wheeling diodes are used to reduce flyback, which is the

sudden voltage spike seen across an inductive load when its

supply voltage is suddenly reduced or removed.

Due to the cheap costs of fast IGBTs with

included free-wheeling diodes, choices such as HGTG20N60A4D

(600V 40A) or FGA60N65SMD (650V 60A)

or the well known Warp2 series from International Rectifier

(such as the IRGP50B60PD1) are

excellent choices. However,

I had some HGTG30N60A4D IGBTs on hand and have decided to use them in this SSTC.

A closer look at our 30N60 transistor

Taking a look at the datasheet for the 30N60s,

we see that they are actually rated for 18A operation at 200kHz

(390V). If we look at the Current Rise Time / Delay Time / Fall

Time etc, these all add up to 225ns. The general rule of thumb

is to keep the switching time no more than 10% of each cycle.

Since the transistors need to switch once every half cycle, we end up

with a maximum frequency of about 222kHz. For reliable

operation, we shall try to stay around or below this frequency

at the specified 18A. Note that many Tesla Coilers end up

running the transistors at higher frequencies and get away with

it. For example, the famed IRGP50B60s have a rule-of-thumb

operation frequency of <276kHz, but they are known to operate up

to 300A at 400kHz. This however decreases reliability.

Finally, note that the 30N60s have a pulsed

current rating of 240A which is great - we will be approaching

or even exceeding these pulsed ratings in DRSSTC mode! These

days however, manufactures tend to skip over the actual pulsed

rating and simply rate the transistor's pulsed rating by twice

of the operating current. Because SSTCs tend to run the

transistors for long durations or even continuously (versus

several 10s of us in DRSSTCs), we shall try to keep within

continuous specs for reliability.

Inverter Driver

With our inverter built, we need to find a way

to switch them on and off correctly. This is where our driver

comes in. It's goal is to switch the inverter at the correct

frequency so we achieve resonance. It also has to be powerful

enough to charge the gates of our IGBTs quickly.

Gate Drive

Driving the gates of these transistors requires

a powerful gate driver which can supply a hefty current. Think

of the gate like a small capacitor which needs to be charged up

before it switches. We would like the gate to be turned on as

quickly as possible. Fortunately, there are special MOSFET

gate-drive chips which do this all for us. The most commonly

used are the Texas Instruments UCC27321 and UCC27322 fet

drivers, popularized by Steve Ward's designs and now used

everywhere. They are single

channel inverting and non-inverting drivers, with a 9A drive

capability with an enable pin. The enable pin is important for

us if we want an easy way to control the driver via our

interrupter. Hence, Tesla Coilers usually use the UCC2732x

together to create a +- Vcc (usually 12V or more) signal to drive

the gates.

To simplify things even further, I have instead

found and

used the UCC27425 which combines an inverting and non-inverting

driver all in one 8-pin chip! It also comes

with its own enable. The drawback is its lower power capability

(4A), but that's fine for a small coil.

Drive Isolation (Gate Drive Transformer)

Driving the transistors is a simple exercise for

a power engineer, but more challenging for a hobbyist. We cannot simply connect the driver output to

the IGBTs. They have to be electrically isolated from each other.

Two main options exist - a dedicated driver for each IGBT

connected via opto-couplers, or a small gate drive transformer.

The advantages of opto-isolators include precise control and

minimal signal interference, but require additional components

and complexity. The GDT on the other hand, is much simpler to

implement, produces good results and is significantly cheaper.

The GDT is an obvious choice. Note that there are only *some*

cases where a GDT can be used (i.e. cannot turn on or off for

extended times unlike opto controls).

Care must be taken when making your own

GDT. It needs to be accurately wound on a suitable ferrite core,

and isolated properly. The

best way to test if a core is suitable is to wind a few test

windings on the core, connect one end to a signal generator

(square wave) at the planned frequency of the coil, and scope

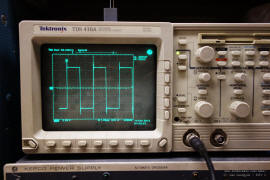

the outputs with an oscilloscope to make sure the signals come

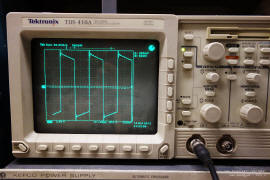

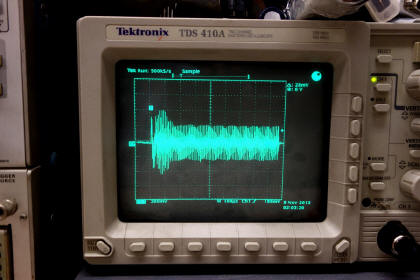

out looking more-or-less square. In the above photos, the left

photo shows the scope when directly connected to my signal

generator. The right photo shows the output of my completed GDT.

Note that you cannot simply use any toroid you

find as a GDT! It needs to be a suitable ferrite material (no

iron cores), and the only reliable way to make sure it will work

is to do the test I did above, so you do need a scope and signal

generator at the very least.

I am driving the primary of my GDT

with +-12V. However, in order to turn on the gates of my IGBTs

as quickly as possible, I want to drive them at a higher voltage

of 18V. Hence, my primary of the GDT is wound with 8 turns and

the secondaries wound with 12 turns to provide a 1.5V step up.

Scoping with the oscilloscope shows that it works (see photos

above, noting the units)! Above is a photo of my completed

GDT.

To protect the gates, it is useful to add

something like 22 or 33V zener diodes / TVS across the gate and

source to protect the gate in the event of any voltage spikes. I

have omitted them in my design for this coil.

Frequency Generator

The frequency generator drives the frequency of

the primary coil and it should be able to be adjusted to run at

the resonant frequency of the secondary coil. The most obvious

way is to use an external frequency generator, such as a TL494,

which was done on the first generation SSTCs around the start of

2000.

However, this is quite ineffective in practice. When a spark is

produced at the top of the secondary coil, it has its own

capacitance and this decreases the overall resonant frequency of

the circuit. This puts the coil out-of-tune.

A common method of use simply calls for a

vertical wire being places a few centimeters from the coil,

around 15cm in length. This acts as an antenna, picking up a

small sinusoidal current. Using schottky diodes (diodes with a

low forward voltage drop, and hence, fast) to clamp the signal

to ground and +Vcc, so we do not fry our drive chip (Germanium

diodes like the 1N60 are fine also), we obtain a square signal

to the input of our driver. Hence, the coil is self-tuning. This

method represents the easiest and most convenient way and is

what my SSTC 1 uses. The disadvantage of

this is the somewhat finicky positioning of the

antenna.

Another method is obtaining feedback using a

small current-transformer on the secondary coil. This is

constructed by wrapping around 50 turns of wire on a small

ferrite core with the secondary wire going through this ring on

the ground side. Care must be taking to ensure the right

phasing, which is simply done by reversing the direction of the

secondary wire if the phasing is wrong. I find this to be more reliable than the antenna, and

removes the need for a fragile wire sticking out of the driver.

Thus I have employed the use of secondary current feedback.

Likewise, schottky diodes clamp the output. The output of the

current transformer is fed through two logic inverters (74HC14

or similar) which cleans up the signal to the Mosfet driver.

There are other methods also but they are beyond

the scope of this page :-)

Interrupter

The interrupter can be any circuit which gives a

1-bit signal (on or off) to the driver. There are many ways this

can be implemented (or as mentioned, not implemented at all).

Perhaps the most popular way is using two 555-timers together,

one running in astable and one running in mono-stable. By

varying the resistors connected, one can vary the pulse-width

and the frequency. See my SSTC 1 which

uses such an interrupter for more details. The output of the

interrupter is usually some kind of logic signal (usually 0V for

0 and 5V for 1), and this can be fed directly into our drive

chip's enable pin.

However, especially when running large powerful

Tesla Coils (where the spark length can make the coil very

dangerous to be near), it is often a good idea to control the

SSTC from afar, necessity the use of an external interrupter

powered by a battery with a wire leading to the coil (a shielded

RCA cable is usually used). For an even safer operation (and

greatly reducing interference from the RF produced by the Tesla

Coil), fiber optic can be used to transmit the

signal. This way, the interrupter can be completely electrically

isolated from the Tesla Coil. This was implemented in my DRSSTC 1

using a standard plastic fiber optic cable, and my

DRSSTC 2 using a 62.5um multi-mode ST

fiber-optic interface.

For simplicity, elegance and compactness, I have

decided to integrate the interrupter directly inside the SSTC

this time since it will be in a shielded box. I have also used an ATTiny85 micro-processor to

produce the interrupter signals instead of a standard 555

timer. This saves me a bunch of space on my PCB since instead of

having two 555 chips and a bunch of capacitors and resistors, I

only need one 8-pin microcontroller! Two potentiometers make a variable 0 to 5V output, which

feeds into the ATTiny's ADCs. This voltage is read and allows me

the control the Pulse-Width and the Frequency, from about 1Hz

to 254Hz, with a pulse width of around 10% capped at 1.5ms (user

adjustable).

Two of the ATtiny's pins are used to measure

voltage from two potentiometers. These have a 10-bit precision

(out of 5). Using the values, I scale the pulse-width and the

frequency. One output goes directly to the UCC mosfet driver via

a 5k resistor, and another output simply lights an indicator

LED.

Construction

2013

Secondary and Primary Coils

Secondary Coil

In SSTCs, there are a few things to focus on when designing the secondary coil - we want

to have good coupling but not too much so that arc-over (from

primary to secondary or racing sparks on secondary) occurs,

and we want to increase our primary inductance to reduce

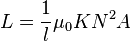

magnetizing current (but not too much since more current = more

sparks). The equation below gives L for a solenoid.

L = inductance in henries (H)

μ0 = permeability of free space = 4pi × 10^−7 H/m

K = Nagaoka coefficient

N = number of turns

A = area of cross-section of the coil in square metres (m^2)

l = length of coil in metres (m)

As a result, most SSTCs have 'short' secondaries, i.e. have a

small aspect ratio of about 1:1.5 to 1:3 (versus 1:4 to 1:6 for normal SGTCs)

and cylindrical primaries (good for high coupling). Additionally, they are usually quite fat

in diameter (this increases

primary inductance because the primary is usually wound as a

tight coil around the secondary coil). From the equation of

Inductance of an air-core coil as above, we see that increasing

the turns increases L to the square, and increasing the diameter

of the coil also increases the inductance by the square (since

area increases by the square of linear dimension).

Additionally, we want to drive our primary coil at a suitable

frequency - too high and we run into problems with our inverter

transistors since they do not like being switched too fast. Too

low and the size our our coil becomes physically too large.

This is a run-through of how I designed my secondary coil.

First, I chose my frequency to be in the ballpark of 250kHz. If

you recall the brief analysis in transistor selection

above, we found that we should keep below 222kHz as a rule of

thumb. However,

making the resonant frequency too low requires a physically

larger coil, so a balance needs to be made... Next I knew I had some extra PVC pipe in the 3.5" dia size. I also had a bunch of 34AWG wire on hand, which

occupies about 159 turns per inch. With a winding of 7 inches

(or a 1:2 ratio), I

get roughly 1100 turns. This gives me a resonant frequency of

371.27kHz. Adding a 8" by 2" toroid on top, I drop the resonant

frequency down to around 251kHz. A winding of 6 inches gives

272kHz. Hence, I can simply wind the coil for about 6 to 7

inches with AWG34 on a 3.5" secondary and add a small topload.

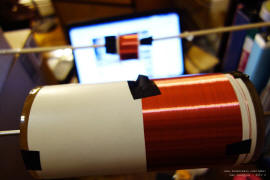

With the calculations done, I proceeded to wind the coil. I

wound enameled copper magnet wire (34 AWG) on a 7 x 3.5" PVC tube for a length

of 6.25". This was done by hand as shown above, and took

just about an hour and a half with short breaks in between. The

reason why coilers use magnet wire is because of its thin

insulation which allows us to get as many turns per unit length. With a 98% fill-rate, this should give me about 970

turns. Together with an 8 x 2" aluminium toroid, JavaTC

gives me a calculated secondary resonant frequency of 256.99kHz

with a secondary Q of 168.

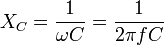

Here is a screenshot of my

JavaTC simulations. The results are from a 3.5" x 6.25"

secondary winding of AWG 34, giving me about 972 turns for about

98+% fill, with a 10 turn secondary 3.7" x 1.25" x 10 turns of

AWG 14, and a 8" x 2" toroid. Notice adding the

primary coil does change the resonant frequency and other parameters. It also

shows (to-scale) what the final product will look like!

*update - new primary coil made, see below for more details *

Finally, acrylic discs were cut and glued together to

form endcaps, which were then affixed to the secondary coil with

two small 2-56 screws per cap. Finally, the coil was given

several coats of oil-based polyurethane varnish. I used Minmax Clear Gloss

polyurethane, but any type of varnish should work fine.

Remember that several thin coats are always better than one

thick one (and it dries a lot faster!).

Three holes per side of the secondary coil were drilled and

tapped to accept 2-56 screws, which then hold the end-caps in

place. Finally, each end of the wire was terminated by soldering

it onto a short copper strip taped onto the end caps. The last

photo in the top right shows how I affix it to the base plate,

with a grounding strip connecting the ground wire to the

secondary coil. The total resistance of the entire connections

from topload to mains ground is just slightly over 200 Ohms.

Primary Coil

For the primary coil, this is made by simply winding a few turns

of thick wire (>=14AWG) at the base of the secondary. For a

normal SSTC, we generally want good coupling and many turns to

reduce magnetizing current. Around 6 to

9 turns should do the trick, but turns up to 20 are also common. Experiment around and see which

produces the best result with a suitable steady-state current

and minimal heating of the inverter.

One important note is that it is important to add a DC-blocking

capacitor in series with the primary coil across the inverter

output. In half-bridge configuration, two capacitors can be used

in series across the + and - of the bus rails, with one end of

the primary connected to the bridge output and the other to the

middle of the half-bridge. This capacitor should be a small

fraction of the bridge impedence (Vout / Iout), and should be

set to be well above the resonant frequency. Typical values

range from 1 to 6.8uF, and are typically film capacitors.

Note that the reactance X_c of the capacitor is inversely

proportional to the capacitance, so the fairly large DC-blocking

cap (vs say a resonant capacitor for DRSSTCs which are on the

order of tens of nF) has relatively low reactance. The DC

blocking cap comes from switch-mode power supply designs, where

saturating a transformer can destroy the transistors due to high

currents. Likewise, without the capacitor, if one transistor

latches on for too long, this causes a short between

the bus capacitors through the transistor, which can lead to the

potential death of your bridge. Especially for half bridges, any

DC imbalance can also add a DC bias current without the

capacitor.

That said, many people have built coils without the DC-blocking

cap, and it is not necessary especially for small

coils. However, they can save the day in some unexpected

circumstances and are relatively cheap, so it is prudent to add

one. I've used a 4.7uF MKP metalized polypropylene film

capacitor in series with my primary (you should use a good

quality polypropylene capacitor - I used 4.7uF because I had one

on hand, but any capacitor around this value should be fine).

05 Nov 2013

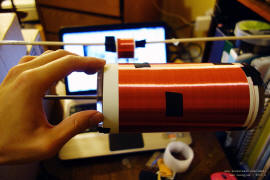

* Updated Primary Coil *

If you browse around some of the earlier photos of the coil, observe

that it used some thin blue wire (7 turns). I found out that

while this produced good sparks up to 8.3", the coupling seemed

to be a bit too high causing the occasional

secondary-racing-sparks problem especially if a sharp breakout point was

not used. So I decided to build a slightly better primary coil.

I designed and laser-cut some acrylic holders for the primary

coil so it formed a structure about 4.56" diameter around secondary

coil. This was placed slightly under the beginning of the

secondary coil and uses 14 AWG wire for 6

turns giving a winding height of 0.65".

JavaTC returns a coupling of around k=0.25 or so (full results

shown above), with the primary inductance of 7.412uH. The

secondary has a resonant frequency of 252kHz. The photo

below shows the new primary supports! For reference, the old

primary had a coupling closer to 0.28 and inductance of ~8.5uH.

From these values, the reactance of the primary can be

calculated to be X_L = 2pi * f * L = 11.74 ohms. Since the DC

blocking cap presents a low reactance (we'll ignore it) and

assuming the primary resistance to be negligible, with a 169V

(120 * sqrt 2) peak to peak square wave across the primary, we

should see a peak current of about 14.4 Amps! This

increased current compared to the old primary should give larger sparks.

So how well does theory match up with the real world? I hooked

up a 300 turn current transformer (terminated with a 47R

resistor) and measured the current of the primary with an

oscilloscope (photo above). From the waveform, the steady state

current shows a 2.23V max (this was a 10x probe). This means a current of 0.0474A

through the resistor, or 14.23A through the primary - it

matches what we expected from our calculations.

Note that the peak current goes up to about 30A (27.9A as seen

in this waveform) before streamer loading on the secondary, but

the steady state current remains around 15A regardless of the

length of the pulse width. If you recall our quick analysis in

the transistor selection part above, you can see that

this is actually within or at least close to ratings of

our IGBT (18A continuous at 200kHz) and should be able to run happily for long periods of

time :). It's always good to have a coil run within specs -

something difficult to do in DRSSTCs!

For those of you designing your own primary coils, it is good to

decide on a current you wish to run at (anything below 30A

should be

good for reliable operation or even 50A for well heat-sinked

transistors), and add/remove turns while making sure your

coupling doesn't get too high and cause racing sparks on the

secondary.

Toroid

I used to make my own toroids out of ducting and aluminium foil,

but have also had good results with hand-made foam toroids

wrapped with foil as well as aluminium ducting toroids. However,

I decided to buy a cheap stamped toroid. It measures

just about 1.9" x 8".

I also spent some time on the lathe sanding it to remove some

marks left over from the stamping process. This gave my toroid a

nice spun-aluminium finish. According to my calculations, the

effective topload capacitance is just about 8.3pF putting my

total resonant frequency around 250kHz (it's closer to 308kHz

without the toroid). Finally, a sharp breakout point was added.

This was simply a wire cut at an angle to produce a pointy tip.

Enclosure and Box

Part of the inspiration for the project came about when a friend

of mine threw out a spoilt computer power supply unit. It came

in a nice black box with an IEC power input jack, ground connections

and a nice big fan all integrated. I decided to work within the

constraints of this box for my SSTC. The goal is to create a

very simple, modular coil which I can transport around easily

and quickly.

The box did place a constraint on how large my components could

be. One thing I had to compromise was the size of the heat-sink

for the IGBTs. To make up for this, I added two headers for which I would be able to connect two fans. This large flow

rate combined with my low duty-cycle should be

sufficient.

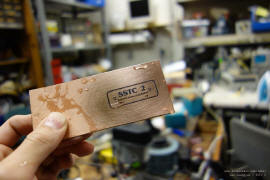

Finally, I wanted to make some sort of label for my Tesla Coil!

This was simply done by etching on a spare piece of PCB a little

label + the BPS and PW labels for the two potentiometers. This

turned out beautifully and the label is attached to the box via

two 2-56 brass screws. A thin coat of varnish was applied over

the label to prevent future oxidation of the copper. Finally,

note the laser-cut platform for the coil-forms, as well as the

convenient hole in the box for the grounding and primary wires

to go in to. The platform also allows intake for the big 120mm

fan which provides cooling for the whole coil.

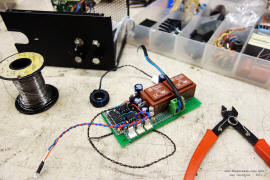

Power Bridge (Half Bridge)

My original plan was to etch my own PCB in making the inverter.

However, since this would be done in-house, it would be

challenging to make a double-side PCB, which is essential in

creating a low-inductance bridge. Fortunately, I came across some old PCBs created by my

friend Bayley. A few months ago, Bayley was working on a small

single-board DRSSTC, and had some spare old-revision boards left

over. Conveniently, the inverter section was physically separate

from the driver section. So I cut the PCB in half and used the

inverter side to mount my bus capacitors and IGBTs. This

low-inductance layout should hopefully remove the need to add

bulky film snubber capacitors and TVSs.

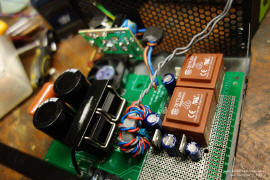

Here you can see how the layout looks like inside the

power-supply box. One side with the head-sink and the two

electrolytic capacitors is the half-bridge with the GDT

installed in place. The right side is the control circuit board,

dominated by two small 12V transformers. Everything is a tight

fit, but works out well. The heat-sink for the two TO-247

transistors is a bit on the small side, but the large fan at the

top of the box + and additional small fan inside, coupled with

my low duty cycle should help keep things cool. Remember that

the goal of this project was to keep things simple and compact,

but you should probably add a bigger heat sink for your coil.

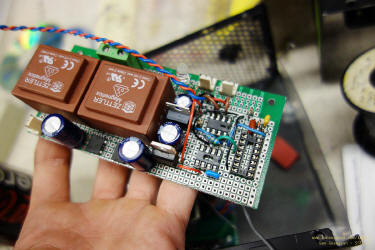

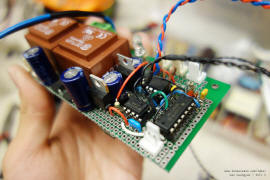

Driver

The driver circuit was simply assembled on a perf-board and

connected via wires and solder bridges. I decided not to etch my

own PCB this time, because wiring up this way should be easy

enough for a small circuit. After all, it only uses three chips -

the ATtiny interrupter, the UCC and the Hex Inverter (which could probably

be emitted)! The logic power comes

from a small 120V to 12V transformer which is full-wave

rectified and regulated via a 7812 and 7805. A generous amount

of filter capacitance was added on the logic bus. A separate

transformer provides 12V for the two computer fans used to cool

the electronics.

Above is a photo of the more-or-less completed driver (without

the chips yet). The bulk of the board is taken up by two small

120V to 12VAC EI30 transformers, good for supposedly 1.5VA each. The

left transformer has two 3-pin molex headers for easy

connections to the fans. Note that the output is rectified by

two bridge rectifiers and have their own filtering capacitors.

These two circuits are separate.

The other filtered 12VDC rail is regulated by a 7812 and chained

with a 7805 for my 5V rail running the ATtiny and 74HC14

inverter IC. The output of the ATtiny85 is sent to the input of

the UCC mosfet driver (via the blue resistor). The two other

3-pin headers at the top of the board go to the potentiometers.

Another header was subsequently added for secondary input to the

74HC14 for feedback. Finally, a low-voltage lock-out was also

added subsequently (yes they all fit nicely on the board).

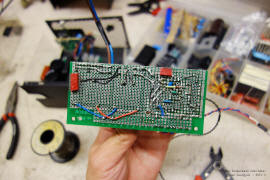

After a bit more work, all the components are populated.

Note the two LEDs - one is directly soldered on the board and

serves as a power indicator LED. The second is connected to the

second output of the ATTiny85, and provides a visual indication of the

output of the interrupter signal. Finally, the 50-turn secondary

current transformer is also visible. The bottom of circuit board

looks a bit messy, but it works well. The circuit was tested

carefully and found to work well first time around :-) with no

problems!

The board was inserted into the case (held in place via two

screws), and plugged in. A few more

things to note here - I used some relatively thick plastic sheet

as a safely insulation liner between the bottom of the PCB and

the metal case. Also, you might

note the single pole and push-button switches installed at the

front of the box. This was meant to control the interrupter

signal, but I subsequently removed them for simplicity. Turning

the Freq potentiometer to 0 automatically turns the interrupter

off. This is all controlled via

ATTiny85 programming. Finally, yay for the Aqua LED (it really

looks a bit more green in real life)!

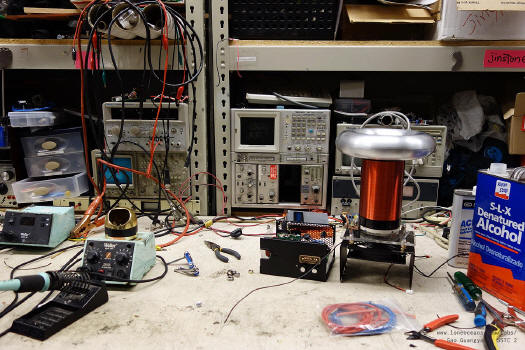

Putting it all together

With all the parts completed, it's time to put them together.

Above shows SSTC 2 with the secondary and topload all securely

in place (along with the messy workbench!). It's now time to

test the coil!

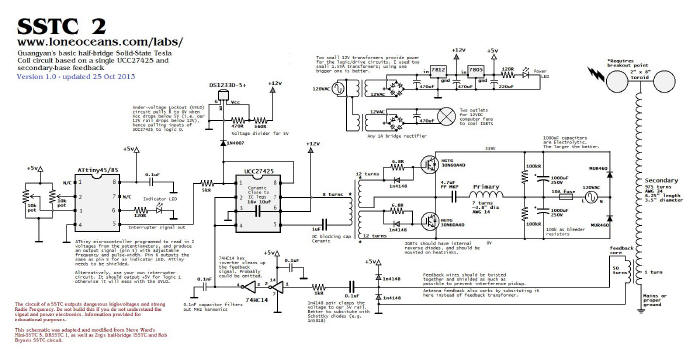

Schematic & Interrupter Code

And as a reward of reading till here, here's the schematic for

the entire SSTC 2 for your reference! I've tried to make it as

straightforward and understandable as possible, but you should make

sure you understand every component of the circuit before building it.

This schematic was modified from the original designs of Steve

Ward's SSTC 5 schematic, whose contribution to the Tesla Coil

community has been immense. The original designed used an

antenna feedback and dual UCC Mosfet drivers for the GDT, and a

555 interrupter. I replaced the interrupter with a programmable

ATtiny microcontroller instead. Finally, with more inspiration from Bayley's

and Zrg's SSTC, I replaced the dual UCCs with a single UCC

driver capable of dual invertering and non-inverting enables to

simplify the circuit even more. An additional under-voltage

lock-out is employed for safety but could be omitted.

I believe this circuit is almost as simple as it can get whilst

still being generally quite reliable. I've also added as many

notes to the circuit. The voltage regulation circuit can be

simplified with a single transformer. For feedback, you can use

any sort of feedback (antenna, secondary, etc), and the 0.1nF

filter cap can also be omitted since it does introduce some

delay in the feedback loop. If I were to put it in again, I'd

put it before the 7414 inverters directly on the output of the

CT instead.

Now the final piece of the

puzzle is the interrupter code. I've presented it here for you

to use. Feel free to edit it to suit your needs! The file is in

an Arduino .ino format and was designed to be programmed into an

ATtiny85/45 micro using the 8Mhz internal clock and using the

Arduino as an ISP programmer. Download the latest

version 0.63 here.

For those of you who no not have an Arduino, you can download

the Arduino IDE, compile the code and burn the .hex code the

normal way. If you do not have any experience with

microcontroller, you can simply build a standard 555 circuit

(see my SSTC 1 page for details), or any other interrupter of

your choice.

If this project has been helpful in any way, I'd be happy to

hear from you and the results of your coil!

Enjoy and be safe!

Results

Mid Oct 2013

Testing the Coil - Preliminary tests

With all the components done, it was time to

test the coil! I was still not done with my actual secondary

coil yet, so I used a temporary secondary coil lying around the

workshop. It measures 12" x 2.5" with 34AWG. A 6-turn 3.5"

primary was used with a 6x1.5" + 7 x 2.5" toroid, bringing the

resonant frequency to about 300-350kHz.

It is prudent not the test the coil at full

power first, so I ran the coil off a DC power supply. Notice the

two switches in front of the control box, which I used to

connect/disconnect the ATtiny85 output from the UCC. It turned

out to be a bad idea because the UCC input goes to high when it

is not connected = CW mode, but can be easily solved by

connecting to ground via the switch. Instead, I removed the

switches and changed my programming of the ATtiny85 to turn-off when

the BPS knob is turned to 0. This simplifies the control of the

coil. The coil starts to oscillate at around 20VDC, and I tested

it up all the way to 90VDC on the bus. The coil made small

sparks and generated a very strong RF field around the coil,

which can be felt in terms of burning-tingling sensations when a

metal object in the vicinity of the coil is touched. The coil is

working!

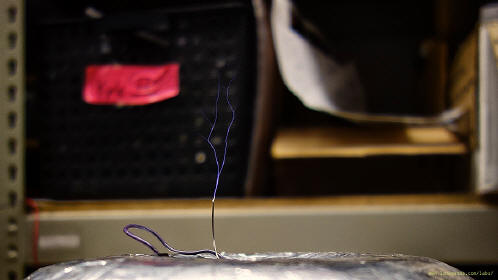

First Light!

The first time a Tesla Coil makes sparks is

generally regarded as the 'First - Light', and is considered a

milestone event by Tesla Coilers! After first-light, usually a

bit of tuning will need to be done, but the fact that the coil

makes sparks is generally a good indicator that the main

components are working correctly. This photo records this

moment!

Here, the coil is running at a relatively low

BPS (around 50 - 100Hz), with a pulse-width of about 400+us. The

input voltage is just about 80+VDC across the bridge, which is a

lot less than the 340VDC it will see eventually. Here, it just

about makes 2.5 - 3" sparks. Also, the coil is running with a

separate secondary from the one I will be using (it's a 12" x

2.5", 34AWG coil with a 6-turn primary on a 3.5" form, with two

small toroids, bringing the resonant frequency to around

300+kHz). During this test, my secondary coil was still not

completed yet.

Testing the coil - with actual primary and

secondary

After the varnish on my actual secondary coil

had dried, it was time to test it! As before, I began by winding

10 turns of wire as the primary coil around the base of the

secondary (note the PVC sheet in-between as insulation), and

connected my bridge to a 0-100VDC power supply. The coil sprung

into life easily, but it was clear that when I raised the

voltage over 80V, I started to get skips (i.e. the interrupter

would send a signal but the coil would not oscillate).

This made me try various techniques including

adding more feedback turns on my secondary feedback transformer,

but it did not solve my problems. As a last ditch attempt to

figure out what was going on, I remove the secondary feedback

and use a bare wire antenna - this worked perfectly!

However, notice in the setup above that my coil

was running with the electronics outside. It turned out that the

ground wire from the base of my secondary to the control box was

picking up interference from the primary coil of my Tesla

Coil, causing it to give unreliable feedback. This makes

sense because above a certain threshold of voltage in my

primary, the current will be large enough to produce significant

interference in my ground wire. This problem was solved by

putting the ground wire inside the grounded case. The coil

then runs very happily off secondary base current and is what I

use in my final design.

I then switched to a variac for input to my

bridge, and slowly cranked up the power. Above around 100VAC in,

I started to get small flash-overs on my secondary coil -

hinting at [1] Insufficient insulation, [2] too much coupling

and [3] some slight asymmetry in the coil. To solve [1], I added

a second layer of insulation using an acrylic form. For [2], I

reduced the number of turns from 10 to 7, and for [3], I tried

to make the coil more symmetric. Ideally I'd have a bit more

spacing between the primary and secondary coils.

With all this done, I assembled everything back

together into the case and tested it at full power. The coil

works and performs admirably!

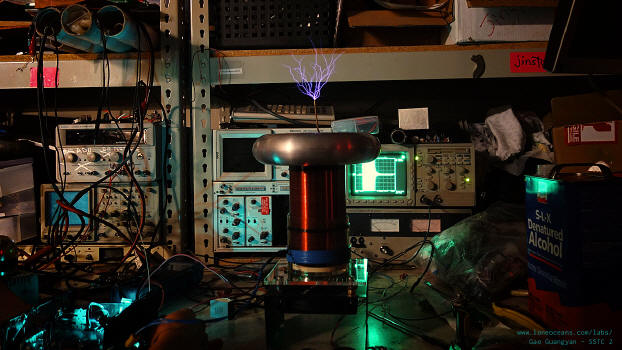

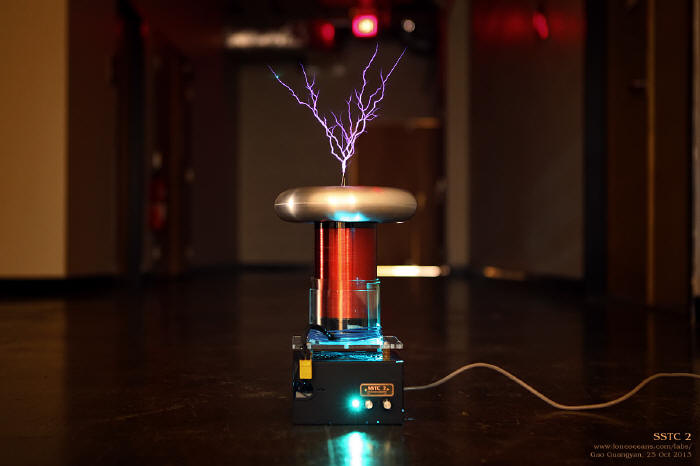

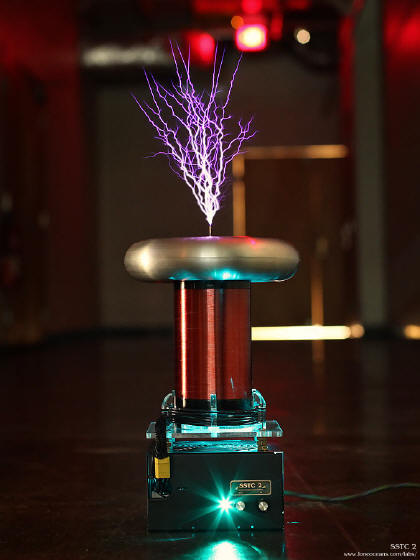

Results

I'll let the photographs do most of the talking!

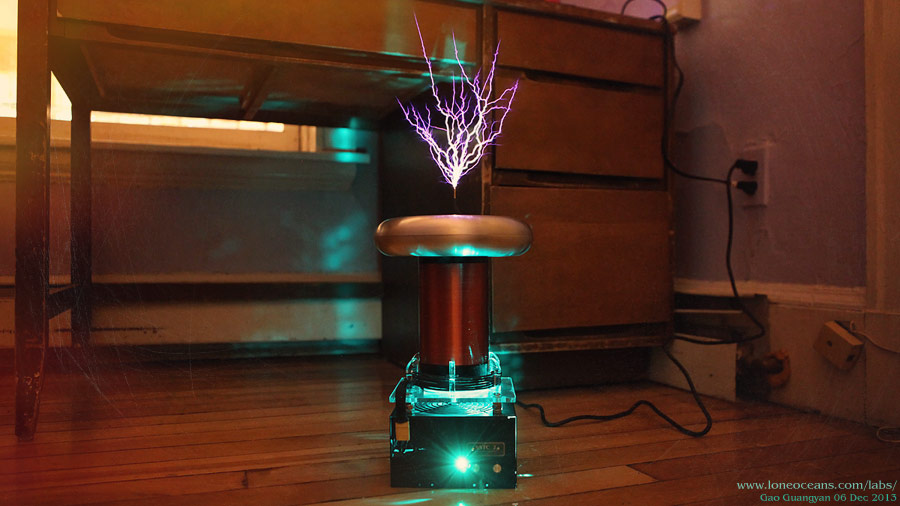

Above shows the coil just after being assembled

together. It makes just over 7.5" sparks to air, which is not

bad considering the secondary winding is only 6.25 inches. Right

now the coil's interrupter runs from 1 Hz to ~500Hz with 1000us

on-time max and a 20% max duty cycle. The photo above shows the

coil running at 1000us pulses (120VAC input).

I'm glad that the coil came together quickly and

as planned and I'm happy with the performance. I should be able

to push even bigger sparks but running this at higher voltage,

but the goal of the project was the make a small, reliable

demo-coil in a weekend. The project actually wound up taking 2

weekends, but I think it was worth the extra effort to make

things look nice. It also met all my design goals resulting in a

compact, portable and reliable Tesla Coil suitable for demos.

Here, SSTC 2 is making around 8" sparks with 1000us on-times.

Right now there are no plans to made additional

modifications to the coil except for maybe tweaking with the

interrupter code and perhaps lowering the overall duty cycle to

10% max but increasing the max pulse width to 2ms. Till then, I

hope this page has been helpful in your quest to design your own

SSTC :).

01 Nov 2013

I made a few small tweaks to the interrupter

code. The coil now runs from 1 to 254Hz and pulse-width from 0

to 1.5ms for thicker more fiery sparks. I also updated the

interrupter code which is available for download above.

I'm now happy enough to say that the coil is

done! Some final observations include that it still does need a

breakout point to breakout, otherwise the coupling seems to

become a bit too great leading to occasional racing sparks on

the secondary, but this happens quite rarely if I don't use a

sharp breakout point. All is fine with a sharp point. I believe

this is easily fixed by simply making the primary coil very

slightly wider instead of directly onto the secondary coil.

Removing one turn would also probably help. Best spark-length to

air to date is now 8.3 inches!

05 Nov 2013

Final results with New Primary Coil

As mentioned above, I decided to add some

real primary stands to reduce the coupling, and will also

allow me to remove the need for the somewhat messy plastic

wrapping around the secondary coil. By increasing the diameter

of the primary, I was able to reduce the number of turns from 7

to 6 which allows slightly higher primary current due to its

lower inductance, all while reducing the coupling for reliable

operation.

With the new primary coil, everything looks a

bit tidier and spark length is now officially just hovering

around 9 inches! It also breaks out happily without a

super-sharp breakout point with no more secondary racing sparks

and runs happily at 15A primary current.

The coil also lights up big bulbs wonderfully

with some very curious spark formation in the low-pressure

environment inside a normal bulb. Finally, some overview photos

of the coil in low frequency mode and higher pulse reps.

In the left you can see the coil running at low

frequency pulses at about 2Hz, 1.5ms per burst. This produces

few hot and thick sparks. The second shows operation at 200Hz,

but only a few hundred us per burst. At this power, the coil is

quite loud indeed and the sound resonates in the room and

induces significant RF in metal objects in the room, which can

be felt in terms of RF burns when touched...

Finally, the above photos shows the coil in

action around light bulbs - wireless energy is transmitted! As of now I'll

liked to declare the project a success! It's now time to move on to the next project.

:-)

25 Oct 2013

Halloween Edition!

With Halloween just around the corner, I thought

it might be a fun idea to try replacing the toroid with a

pumpkin! I looked through a few supermarkets trying to find the

right kind of pumpkin - around 8" in diameter, and quite flat,

like a toroid. Unfortunately I didn't seem to be able to find

any around, so I wound up buying a squash instead of a pumpkin.

I then inserted two small wires at the top and bottom of the

pumpkin, with the bottom connected to the secondary and the top

as the breakout point.

It works! The pumpkin (squash) works well as a

toroid. Hopefully I'll find a more toroid-looking pumpkin

another day. Happy Halloween everyone!

Credits

This project was inspired by the great Tesla Coils by

many other people:

- Steve Ward's one-day SSTC 5 as an inspiration for

making this coil in one weekend

- ZRG's simple half-bridge SSTC design which used one

UCC instead of the usual 3732x pair of chips

- Bayley Wang's tinyTesla project which is a tiny

900kHz Tesla Coil much smaller than this one and very cute

- The many great tesla coil and high voltage forums on

the internet which gave me valuable advice

- And everyone else who has helped me in one way or another.

More to come soon!

Back to main page

(c) Gao Guangyan 2014

Contact: loneoceans [at] gmail [dot] com |