|

Mini 40mm Tesla

Coil

Index

|

This project was

inspired by all the other tesla coils out there. Since it is

my first attempt at building a tesla coil, my aims are

to produce a small, relatively good-looking,

working spark-gap tesla coil, more to learn about building

tesla coils, and to gain invaluable experience. This project was

inspired by all the other tesla coils out there. Since it is

my first attempt at building a tesla coil, my aims are

to produce a small, relatively good-looking,

working spark-gap tesla coil, more to learn about building

tesla coils, and to gain invaluable experience.

This page will index my

construction efforts as I update it continually during the

course of my tesla coil construction. It will be updated

frequently, with the most recent ones at the bottom.

Current Status: Under

Construction.. Completed! on 20th November 2003

Now under testing and tuning...

Project status halted since 2004 till further notice (28 July 2004)

Coil currently being improved. (9th August 2004) |

|

Acknowledgements Acknowledgements

The tesla coil is

complete! I would like to thank the following people, for this

coil would not have been completed without them.

- The great people at

the 4hv forums and the-geek-group forums for giving me great

advice and suggestions

- My dad and my mum who sponsored most part of the funding for

the building of this coil and for finding parts and components

together with me, and for spending time and resources, and for

tolerating the noisy coil while in operation.

- All the great tesla coils on the internet which gave me

valuable advice and construction details

- And everyone else who has helped me in one way or another. |

15 Oct 2003 (Wednesday)

|

I

have recently acquired a Neon Sign Transformer for my power

supply. It's the unit on the left. I passed by a Neon Sign

shop and asked for a used/old/spoilt transformer. Luckily,

they had some extras. After much persuasion, they gave me a

supposedly spoilt unit. I

have recently acquired a Neon Sign Transformer for my power

supply. It's the unit on the left. I passed by a Neon Sign

shop and asked for a used/old/spoilt transformer. Luckily,

they had some extras. After much persuasion, they gave me a

supposedly spoilt unit.

It is a F.A.R.T. brand

transformer. (stands for Fabbrica Apparecchiature

Radioelettriche Treviso I think.. this is living proof that a

brand this name can sell so well. It is the best selling neon

sign transformer in the UK by the way.

www.fart.it). It's a 15kV

30mA unit, and weighs around 7+kg. The whole thing is potted

in a resin block and comes with a zinc mounting plate. This

design eliminates rusting and is a very sturdy transformer.

Anyway, I went home and

tested it. Apparently, only one secondary winding had shorted

but the other half was in working condition. This makes it put

out approximately 7.5kV 30mA. Just what I was looking for, for

my small coil. 15kV would be a bit on the high side. Although

this makes it not a very powerful unit (especially since half

of it is junk and taking up extra space), it is still

relatively small and delivers 225Watts with this

configuration. I hope to get around 1 foot arcs from this

system. However, I did not receive any High Voltage cable, so

I guess I'll have to go find some... I'd probably be using

this unit for my coil, unless I find another one in better

condition.

To test if it was

working, I hooked up the mains and powered it on with half of

the high voltage windings. Btttztztzzttzz! It works! At least

I know that this thing can output the 7.5kV at 30mA I need.

Here is the picture of

the arc. 30mA is quite high (quite enough to kill!) resulting

in a HOT fiery arc. I will make a large Jacob's ladder too to

celebrate this find! At least I got this transformer Free.

Tomorrow, I plan to buy materials for my

toroidal top load... I have acquired a large roll of aluminum

tape for $15. I would be constructing the top load and

hopefully the spark gap (set at 8kV) tomorrow. |

18 Oct 2003 (Saturday)

|

Progress has been slow

due to the un-availability of parts... until now. I have

finally got most parts more construction can start. I've

decided on a double toroid design, one large diameter one

resting on a small diameter toriod, for better E-field

shaping.

Toroid

PVC Corrugated Drain Pipe : Larger toroid taped up....

: Complete small toroid with nylon screw.

The small toroid took

around 2hrs to make. The small one is approximately 23 x

5.5cm. (23cm being the total diameter and 5.5cm being the pipe

diameter). A commercially spun toroid would cost well over

$100 new. Building this cost less than $20 and is extremely

simple to make.

Constructing the toroid..

Constructing the toroid..

The first thing I did

was to cut the centre disk out of some surplus plastic I had

lying around. It's about a 12cm dia disk. After cutting with

my saw, I drilled holes around the perimeter of the disk at

roughly 1 inch intervals. These holes will hold the wire used

to tie the PVC pipe to the disk. After coating the disk with

aluminum tape (plumbers tape), I tied the pipe to the disk.

The pipe I used is a 2" Flexible PVC drain pipe.

I just bent the twisted

wire into the grooves of the corrugated PVC pipe. The pipe

will automatically fit around the disk :). It's not that easy

as it looks... Following that I taped the whole pipe up

with masking tape, to provide a smoother finish, and finally,

the aluminum tape. Basically.. it's done! I bought some nylon

screws to attach it to the secondary coil. The larger coil is

still needs to be wrapped with aluminum tape. Over here,

flexible corrugated PVC pipe and aluminum tape don't come

cheap. I thank my parents for supporting me financially :).

That's it for today. I'll continue the other toroid tomorrow.

It's a nice smooth

toroid after smoothening it with the back of a spoon. |

19 October 2003 (Sunday)

|

I completed the toroids

today and fixed the spark-gap together. The spark-gap is not

fully completed as I still need the fans and attach them to

the gap to quench the sparks. More than 4 hours of work today.

Here is the 2mm acrylic disk to be fitted in the middle of the larger

toroid, which has been taped up with masking tape to smoothen

out the ridges. The disk is approximately 21cm in diameter.

The toroid is about 32cm in diameter, and is made from the

same material as my smaller toroid (2" corrugated PVC drain

pipe). Here, the acrylic is being taped up with aluminum tape

using the same method as my smaller toroid.

Looking good.. disk has been attached with

wire to the torus.

Both toroids completed! Everything is

screwed together to a PVC end cap with a nylon screw. Both

toroids took a total of 4 hours to construct. Sure beats

spending a few hundred bucks.. :) There's nothing much to do

after the examinations anyway. The PVC end cap is to

facilitate easy attachment to the secondary coil. Not bad for

my first attempt at toroid making..

Later in the afternoon,

I got more materials and built the spark gap. It's a basic

sucker-gap design, using two copper pipes as the main spark

gap all housed in a plastic box with two fans to quench

the arcs. I realised that those white plastic chopping boards

would be much more ideal than acrylic. It costs two times

cheaper for the same size (if not bigger) and is a whole lot

easier to saw. I only have a lousy hand saw.. a Jig-saw would

save lots of time... Here's my design.

It's

really very simple. The plastic box houses the two copper

pipes, electrically connected internally to the threaded rods

holding it to the box. The two square holes on the side of the

box are made to accommodate standard computer 80mm fans. It's

really very simple. The plastic box houses the two copper

pipes, electrically connected internally to the threaded rods

holding it to the box. The two square holes on the side of the

box are made to accommodate standard computer 80mm fans.

I have a 4Amp power

supply for the fans so it shouldn't be a problem even for high

powered fans. At the low power my tesla coil will be running

at, it shouldn't get too hot at all.

It's looks easy to

build, but it's not without proper cutting equipment :(. The

whole gap took around 2 hours to make, except for some places

which need to be covered up and another fan. The air must be

forced only in between the spark gaps due to the limited

amount of air flow I can get with the fans.

Here's the uncompleted spark gaps made out

of chopping board plastic, 22mm copper pipe, threaded rods,

contact cement and hot glue. The copper pipes are 22mm, 200mm

long each, and the whole cap is 10cm wide. Looking good too

:).

Looks like today has

been a rather successful day. I can't do much during the

weekdays due to school, so I'll have to cram more stuff during

the week ends. I am now left with the filter network,

capacitor bank, secondary coil, primary coil / supports...

lots more work to do. I am thinking of fitting all components

inside a nice box.. |

21 Oct 2003 (Tuesday)

| Not much done today. I made

a simple poor-man's rig and after drying my 40mm PVC coil

form, I varnished it with polyurethane. The set up is

basically a wooden rod through the PVC, stuck with duct tape,

and tied in between 2 chairs.

The

handle is a piece of thick wire and a short copper pipe. The

handle is a piece of thick wire and a short copper pipe.

This allows me to wind the PVC as I

apply the varnish. It's not as easy as it looks. Anyway, I

kept rotating the pipe for about an hour with a fan blowing to

allow it to set before I let it dry for the night. It's

tiring..

Although it's not smooth, I'm going to

fine-sand the uneven parts down before I can wind my secondary

coil!

|

24 Oct 2003 (Friday)

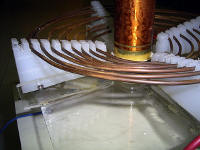

| I completed the Primary

coil today. I have acquired a

Black & Decker 400W jigsaw. It really saves a lot of time.

No more messing around will puny hand saws, this is THE

machine! :)

The base is made of a

230x230x6mm clear acrylic surplus piece I had lying around. I

made 4 supports, each with 9 spaces for the primary windings

and 1 extra should a strike rail be needed to install. The

stands are made out of 12mm thick white plastic chopping board

material. (It's cheap and easy to get from the mart) and are

attached to the base with contact cement and hot glue. The

coil is made out of 3mm thick flexible copper tubing.

Everything was cut and drilled by hand, and even with the help

of the jigsaw, it still took around 2 hours to plan, cut and

fix the mistakes. Here are some specifications:

Primary Coil Inner

Diameter (from the copper tubing): 10cm

Primary Coil Outer Diameter (from the copper tubing): 24cm

Height at outermost turn of coil: 4.5cm

Height at innermost turn of coil: 1.5cm

Copper tubing conductor diameter: 3mm

Inter-turn spacing of copper tubing: 6mm

Total number of turns: 8.5 turns

Geometry of Primary coil: Inverse conical with a 15 degree

slope.

So here it is with a can

for comparison. The back protective layer of the acrylic

hasn't been peeled off yet, which is why it looks brown. I

have attached a 40mm PVC end cap with a nylon screw to the

centre of the coil to allow easier connection of the secondary

coil to the primary coil. Not too bad for a beginner.. |

7th Nov 2003 (Friday)

|

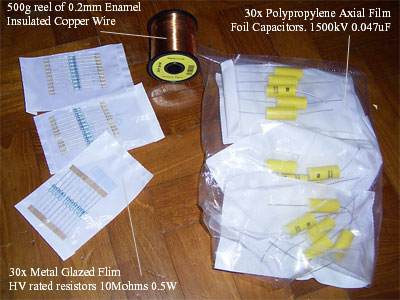

Again, due to lack of

parts, I was unable to continue. Yesterday, my dad helped me

purchase 30 capacitors, High-Voltage rated resistors and 0.2mm

enameled copper wire. I purchased acrylic and thick wires

today, so work can finally begin again.

Today, I completed the

primary capacitor bank using a MMC (multi mini capacitor)

setup. The capacitor is a critical element in the tesla coil.

Critical because it is really punished by the oscillations of

the Tesla tank circuit. The tank current can easily reach a

value of several hundred amperes. The RF (radio frequency)

produces intense stress on the dielectric of the cap.

Professional pulse discharge caps with the values needed for

Tesla coil circuits usually cost between $300 and $1000

(depending on the capacitance and voltage value). So most

coilers try make their own. One of the best approaches is to

connect many small pulse caps in series/parallel and build a

MMC. This seems to be the ultimate solution as a 20nF unit

rated for 10kV in tesla coil use cost below $50 when build

this way - and this is a perfect cap build by professionals

(at least its components), which is why I chose to make a MMC.

According to The Geek

Group's capacitor design chart, the resonant cap for a 7.5kV

30mA transformer at 50hz is 0.0127uF. However, a LTR (Larger

Than Resonant) Cap of a desired value of 0.0191uF(19.1nF) is

recommended - LTR caps reduce the chance of over-volting the

capacitor and transformer, as well as increasing the bang size

and power throughput. In other words, thicker, longer sparks

with less chance of damaging components.

After searching, I

located some nice 1.5kV 0.047uF Film-Foil Polypropylene Axial

Capacitors. They have a very low loss dielectric suitable of

continuous use at high AC voltages and will withstand fast

rise time pulses, as well as having excellent high frequency

performance, exactly what is needed for a Tesla Coil Cap.

After calculating, I

acquired the above components. The 10 Mega Ohm Metal glazed

High Voltage resistors are wired to each capacitor to drain

off the charge after use to prevent shocks, as well as to

regulated the voltages.

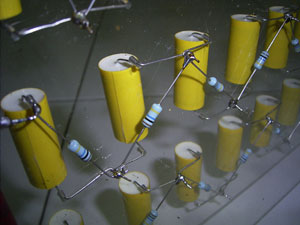

Here's how I wired up

the capacitors. The MMC consists of 24 Capacitors, 3 strings

of 8. The final value of the whole cap bank is rated at 12kV

at 0.017625uF (17.6nF), close to the LTR value of

0.0191uF.

Everything is drawn out nicely on the acrylic

sheets.. and they are drilled and cut all by hand.

The capacitors are slotted in... and their ends

are wired up in series.

Than the resistors go in.. and they are

soldered up together.

The completed capacitor bank!

The completed capacitor bank!

Details of the competed bank.

The bank was mounted on

a 6mm clear acrylic sheet with a 5mm backing. I have to fix

the termination connections at the end of each capacitor

string. My current 40W soldering iron just can't heat the

large copper cable hot enough for the solder to stick.

The completed bank is

visually appealing :-) and took around 3-4 hours to construct.

It cost less than $40 to build - much cheaper than a few

hundred dollar pulse capacitor... |

9th Nov 2003 (Sunday)

| I completed winding the

secondary coil today. My coil form

is a 40mm diameter white PVC pipe. It has been dried and

sealed with polyurethane varnish before winding. I have

decided on a 1:6 winding ratio to add more turns in the

secondary, and to allow use of slightly thicker wire (thin

wire breaks too easily). I used 0.2mm wire (about AWG32?) and

wound about 24cm (actually 23.6cm). With 95% fill, I get about

1100+ turns. The whole coil was wound by hand and took around

1 hour plus.

Above is the poor-man's

winding setup.. I threaded a wooden dowel though the PVC form

with cardboard end supports and the whole thing was kept in

place with duct tape. It was then tied to a chair with wire,

and was allowed to turn freely. (Okay, not so freely... ) The

0.5kg (about 1600m of wire) reel was supported by a surplus

metal rod and could spin freely too. I taped the ends of the

wire with duct tape.. not that nice but at least it works and

sticks well. I'll just varnish over everything in the end...

Winding was tiring especially for the fingers but it was all

over in about an hour.

My first complete coil!

It shines like a copper tube! As you can see, I've left quite

a bit of extra wire at the ends. As I write this, the coil has

been fully coated with polyurethane and is drying. I plan to

put 4 to 5 thick coats, with fine sanding in between each

coats to remove irregularities and give the coil a smoother

finish. |

10th Nov 2003 (Monday)

|

I

have completed coating 4 thick coats of polyurethane varnish

for protection. Due to my lousy coil setup, thick bristled

brushes and lack of skill, the varnish did not apply smoothly,

and there were lots of irregularities (high areas) which

provided a lumpy feeling. I wet sanded before the 3rd and 4th

coats. However, the secondary finish was not what I hoped for,

clear and smooth, but had a sort of 'rusty gold look..'

However, it still provided thick insulation which was what it

was meant for. I

have completed coating 4 thick coats of polyurethane varnish

for protection. Due to my lousy coil setup, thick bristled

brushes and lack of skill, the varnish did not apply smoothly,

and there were lots of irregularities (high areas) which

provided a lumpy feeling. I wet sanded before the 3rd and 4th

coats. However, the secondary finish was not what I hoped for,

clear and smooth, but had a sort of 'rusty gold look..'

However, it still provided thick insulation which was what it

was meant for.

On the left you can see

a mock setup. Nothing is connected yet, it's just stacked up

together. You can see the 15 degree inverse conical primary,

the secondary coil and the double toroid configuration. The

coil is meant to be pushed fully in the end caps for a quick

and easy attachment. Now it somewhat balancing...

The toroid is clearly

not so smooth.. I have tried smoothening it out but it's not

working very much. I shall see how it works out first. |

13th Nov 2003 (Thursday)

|

I made the RF ground rod

today. It's a 22mm x 1' long copper tube. The wire is 3m, 6mm2

7 wire stranded PVC insulated wire and is connected to the

copper tube with aluminum wire lugs with a stainless steel

screw and nut.

I have also made a

safety spark gap consisting on threaded rods, nuts, hex end

caps and a plastic container.

It's a simple but

effective design, and can be easily and accurately tuned.

This is the primary tap made out of a fuse

holder. There's quite a lot of surface contact, and is very

easy to tap.

Almost everything is

done and all I am left with is the tuning and connections! I

can't wait to fire it up!

|

20th Nov 2003 (Thursday)

|

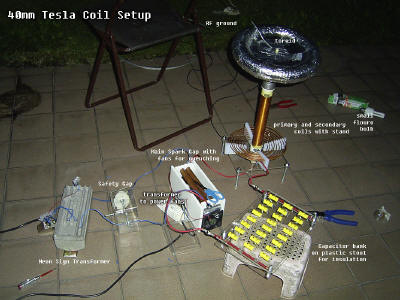

This is my more-or-less

finalized design. Above is the schematic of my coil.

-

Mains is 240VAC

50hz with a 13 Ampere circuit breaker - More than enough

power!

-

I am using a 3 Amp rated EMI filter for

240VAC. Again good enough.

-

The variable autotransformer (variac) is

a 500VA model. I mostly use it to tune my spark gaps.

Apparently, the variac seems to be restricting current flow

and my coil performs better without the variac.

-

I got my Neon Sign Transformer free from

a neon shop because it was 'spoilt'. It's a 15kV 30mA unit

and half of the windings got shorted out, so I am using half

of it, 7.5kV 30mA and the other end is sealed up.

-

(s.g.) is the Safety Gap to protect my

capacitors and the neon sign transformer.

-

L1 and L2 are chokes, basically insulated

wire (same wire as my secondary coil 0.2mm) wound 1 layer on

a pen tube. This prevents the high frequency AC from

traveling back to my transformer. However, I have been

informed that it is not needed and the coil will work

perfectly well without it, so I left it out.

-

(m.g.) is the Main spark Gap made out of

two long copper pipes which can be accurately tuned.

-

C1 is my main MMC design capacitor bank

rated at 12kV 0.017625uF (17.625nF).

-

(p.c.) is my Primary Coil with 8+

tappable turns. I used a small diameter fuse holder as an

adjustable tuner.

-

s.c. is the secondary coil.

-

The toroid is a double toroid design for

more capacitance and to improve electrostatic field shaping.

construction was

completed this afternoon...

*** First

Light! ***

I completed all the

connections and fixed everything up in the backyard.

The 1 foot long RF copper ground

rod is hammered into the soil.. connected to the coil with a

3metre long 6mm2 cord.

Arcs Pictures

(first few lights. Click to enlarge photos)

This is really the FIRST light, without any

tuning. It maxed out 5cm arcs.. not very good.. but it

works... (click to enlarge)

After tuning..: 10cm and 15 cm arcs. This is

after tapping the secondary at turn 6. At first light, it was

as turn 8. Spark length, brightness and noise improved a lot.

This coil can make small fluorescent bulbs light up dimly

nearby. However, I am still not satisfied. There is NO

breakout from the toroid, and with a breakout point, thin,

purple, corona like discharges can be seen. The arcs are

really thin, and I believe my spark gap is set too small.

However, It was time to pack up. I'll do more work soon! I aim

at least 40-50cm arcs! My coil is surprisingly quite

quiet.. I think it's my spark gap. I have fans at my spark

gap, but they have mysteriously stopped working. Now I am

running the gap without the fans for quenching for now..

(click to enlarge)

Here's the setup. Await

better news for the next firing! (Click to enlarge)

Today's maximum arc length from breakout

point to RF ground : 17cm |

22th Nov 2003 (Saturday)

|

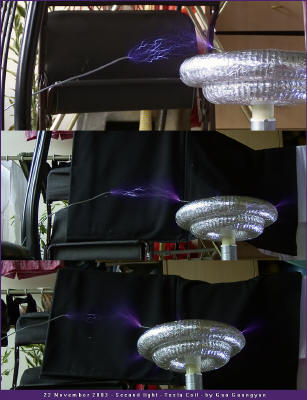

It's SECOND LIGHT today!

Thanks to the people at

www.4hv.org (4hv forums) and

www.thegeekgroup.org

(geekgroup forums) for helping me debug and give suggestions

to improve performance of my tesla coil.

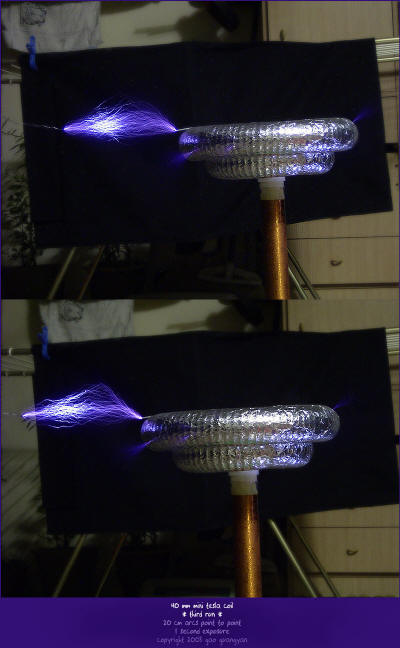

*click on pictures to

enlarge. Due to long exposures, there is significant 'noise'

in the photos.

Everything

is set up and ready for the second run! Everything

is set up and ready for the second run!

Here are some changes I

made:

1. Nice High Voltage

warning sign made

2. I widened the spark gap

3. Coil is now tapped at 5.75 turn at the primary coil

4. Sparkgap is still running without the fan.

So far, the sparkgap and

safety gap is holding up fine.

One design flaw I have

is that the secondary height cannot be adjusted to fix

coupling. Also, I did not make a portable cabinet with wheels

to move it around.. However, it is quite well mounted. I am

pleased with the toroids. Using only one toroid instead of two

led to small arcs.

If I could make changes,

I would try to fix:

1. The power supply. I

believe 7.5kV at 60mA would produce much thicker arcs. My

current arcs are very thin and fine

2. Portability. I have to lug everything around, wires and all

everything I want to fire it up. Packing it is also

troublesome

Now, the sparks.

Everything is the same as run 1 except for the increase space

at the sparkgap and the primary is tapped at turn 5.75 instead

of 6.5 / 6 of the previous run. Second light.

Click to view in full! There is finally

breakout from the toroid! (none on run 1). Arcs are still

wimpy and thin, but they are significantly longer. The coil

runs louder and fiercer too.

This is a 4 second exposure. My digicam

doesn't do well in long exposures and there were A LOT of

artifacts and noise. I tried to clear it up though.. the

bright box on the right is the spark gap. Note the multiple

breakout points. Something that is making me concerned is the

corona at the top of the secondary.. I think I need to

insulate it more before anything bad happens. Right now, there

is no actual streamer. Output looks more like heavy corona and

they are extremely thin and dim... but much better than first

light. The streamers are purplish blue to air and are bluish

white when connected to ground.

Trick photography. This is two photo

overlaid over each other.. about 18cm arcs.

Highlight of the day! My coil has reached

25cm!

The improvements have

significantly improved spark length and overall, the coil is

much louder.

Download Video clip of 18cm arcs:

tesla_2light.wmv (558kb)

The arcs are very thin... notice the safety gap

firing in the first part of the video as a very bright light.

Today's maximum arc length from breakout

point to RF ground : 25cm |

24th Nov 2003 (Monday)

|

Some parts of the coil have been slightly

changed and the spark gap has got a new fan!

The toroids have been shifted down to

remove the secondary corona, and the top part of the secondary

has been slightly varnished (the shinier part) just in case.

Looking good.. :-)

There's the new spark gap! The fan is from

a microwave oven. It's powered directly from the mains and is

very powerful. My previous two computer fans mysteriously

died. Anyway, I needed a step down transformer and a bridge

rectifier to power those CPU fans.. it's much easier and

tidier now. The original fan casing was kept (but was sawed to

fit). A large hole was cut at the side of the gap. You can see

it in the second picture (through the clear acrylic bottom

plate). The fan is connected by a large bolt, friction, hot

glue, silicone sealant and a touch of duct tape to complete

it. The original fan holes were covered with duct tape..

simple but effective. The fan roars now. :-) I am hoping this

would improve things a fair bit.. took around 1hr to make all

the changes with the gap and the secondary setup.

later on at night...

The varnish and silicone has dried. Time to

fire it up. (click pictures to enlarge)

The added fan HAS indeed improved spark

brightness and thickness quite a lot! But there is no

significant spark length improvement. The coil now runs much

louder and fiercer. The noisy fan is completed drowned out by

the spark gap.

Compare this to the photos above. The are

much brighter and powerful. The connected streamer on the

right is 25cm And

here are the best shots of the day...

Much thicker arcs! 20cm. There really is a

difference!

These are really beautiful. Again 20cm

length, but the camera is much closer now.

However, there is still no 'real' large

streamer. I think my toroid is too rough, preventing breakout.

I shall try to smoothened it and see how it all works out. The

new spark gap has really made a lot of difference I am am

pleased with the new results. I still want to improve spark

length and I shall see if I can get it up to 40cm.

Everything's still holding up fine. Ozone smells terrible..

Today's maximum arc length from breakout

point to RF ground : 27cm |

|

Due to

extremely tight schedules since the beginning of this year

(2004), I am unable to do more work on this coil. More work

will resume however. [ 28th July 04 ] |

|

8th August 2004

Tomorrow

is Singapore's 39th National Day! Due to that, there are 2

free days as holidays. (Actually, I can't really call school

holidays 'holidays' anymore because we are given stockpiles of

work which is extremely stressful and pressurizing. School is

definitely not helping the progress of this project! In any

case, work must go on, and thus I have decided to tweak

up the coil. Tomorrow

is Singapore's 39th National Day! Due to that, there are 2

free days as holidays. (Actually, I can't really call school

holidays 'holidays' anymore because we are given stockpiles of

work which is extremely stressful and pressurizing. School is

definitely not helping the progress of this project! In any

case, work must go on, and thus I have decided to tweak

up the coil. I am

still not happy with the performance of my coil. After looking

over my coil design, I found a possible source of problem -

the spark gap. Although I believe it has great quenching power

(from the powerful fan), the problem was that the copper tubes

were connected to the wiring via steel wire and steel threaded

rods. Steel has a high electrical resistance compared to

copper or brass, and other coilers have reported instances

where steel connections heated up a lot. As such, I decided to

dismantle the spark gap and build a new static spark gap. In

the picture you can see the eroded copper pipes. I sanded the

whole pipe down so it was shiny again. The new gap will use

much less copper though...

And there you have it, the new adjustable

static spark gap. It consists of 3 fixed copper rings screwed

down to a HDPE stand. There is one adjustable brass machine

screw as the last electrode. Termination electrodes are all

brass. Although this can't handle as much power as the first

big one, it's much smaller and this time, no steel! I'll

probably add a powerful fan blowing across the gap to assist

in quenching as well as to prevent it from over heating. It's

probably not the nicest looking gap, but it seems to work

great. In the second picture, you can see the gap firing from

caps charged with my flyback. I am hoping at 225W of power,

the gap won't overheat too quick though, otherwise I will have

to make a new one. I'll probably build a stand to encase all

the components too. Hopefully I can find more time. |

|

9th - 10th August 2004

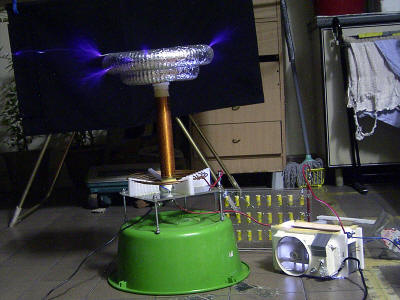

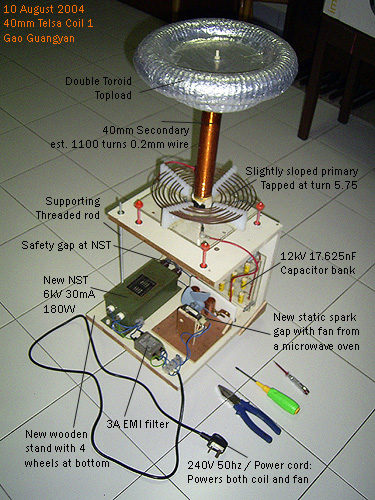

9th August: I built a

wooden stand, with 2 decks (2nd deck supported at one side and

one edge, but still strong). I also cleaned up the dusty

capacitor bank and changed the output lugs to thinner wire.

Why thinner wire? The previous thick wire was too think and

soldering was impossible. Now, although the wire is thinner,

the connection is much better (soldering is possible now).

When I powered the coil

up, it worked for a while, then it stopped. Analysis revealed

that the 15kV 30mA transformer was now fully dead! (Was half

spoilt at first, so I was using the other half, 7.5kV 30mA.

I'm not sure what's wrong as the whole transformer is resin

potted, and thus I cannot dismantle it. Unhappy with the loss

of my 225W unit, I decided to plug my dual MOT power supply

supplying 12kV DC pulses to the coil. Even though I did not

tune it or adjust the spark gap, there was significant arc

length improvement and ground arcs were much thicker. This is

evident in the photos below. I need to get a new NST to power

my coil. My friend, known as raptor, happens to have a

6kV 30mA NST lying around and he is willing to trade with me

it for an amount of magnet wire. Although it's only 180W this

time, I have no other choice... I will be going to his house

to collect it tomorrow.

10th

August 10th

August

Today I got the 6kV 30mA

NST from my friend. The NST is the type which is in a metal

container, potted with a black substance (probably tar). It's

by Standard Electric Works (Hong Kong), and the date says Sep

86 on it. Though a bit rusty, it works perfectly! It's a

center tapped unit.

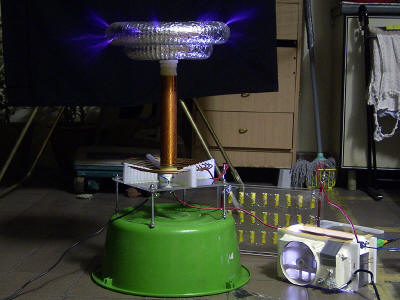

I completed the wooden

stand today. The NST is the green box with a black sticker on

it, and weighs around 4 - 4.5kg. I bought 4 plastic wheels

(cost $5) and screwed them on the bottom to increase

portability.

I also built a bigger,

more durable spark gap. As you can see, there are 3 2inch long

copper pipes bolted to a HDPE board, and a 6mm brass bolt at

the end of the last pipe to make it adjustable. All

connections are now copper or brass, no more steel. I also

have a rather powerful fan blowing right on it, so quenching

should be ok. Everything including a 3A EMI filter is attached

on the stand.

On the right, you can

see the coil running. Performance is ok, though I'm still

unhappy with the spark length. Notice the nice streamers

inside the large 300W light bulb. There is one more thing to

try.. that to the increase the height of the primary to

increase coupling.

I hope to do that soon,

and the coil will be more or less complete! |

|

13-14 August 2004

Time

to fix the primary. Time

to fix the primary.

I cut out 4 6mm x 100mm

x 30mm Acrylic pieces, and drilled two holes at the top 1cm.

These are then tap screwed into the HDPE primary supports,

effectively raising the primary coil by 2 cm to improve

coupling. The hot glue and other stuff were scraped away

(albeit leaving many marks on the acrylic base), and the

supports were glued to it using Chloroform (trichloromethane)

which is like a solvent for acrylic, allowing it to bond

chemically. The second picture shows the aluminum spark gap.

Also, you might have

realized that I have removed the larger toroid from the coil.

I tried with the small one only, and arcs seem best at turn

4.5 to 5. Streamers are now longer! (Primary would be tapped

at turn 5.75 for the large one and the small one together).

More test and arc photos will be taken tomorrow. I hope to

improve spark length even further! |

|

14 Aug 2004

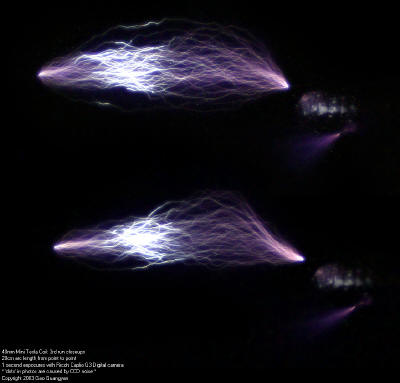

I powered up to coil today. Primary is

tapped at turn 5. I did something different: Since the coil is

now running inside my house (instead of in the backyard), I

can't get a proper RF ground without running a very long wire.

As such, I connected the bottom of the secondary winding to

the first turn of the primary. This configuration is similar

to an Oudin coil/resonator. Although this configuration

eliminates the need for a RF ground, and also eliminates the

possibility of a primary or secondary strike, it injects

dangerous primary AC currents into the output streamers.

Performance is most satisfactory! I guess it works without

much loss in a small coil like this one.

The first photo shows the coil in action

with a metal rod (stuck on a wooden pole of course) drawing

arcs off it. The second photo is a long exposure (a lot of

digital noise) of the coil in action, and the last photo is

the coil with a breakout point.

The photo on the left is

probably the best photo of the coil actually producing

streamers. Performance has indeed increased! Note that without

the larger toroid, there are even more streamers. I

hypothesize that the toroid is either too small, or it is too

rough. For the time being, I'll stick with this.

Today's maximum arc

length to ground is 25cm, and that's which 180W. Previously at

225W, maximum arc length was only 27cm. I am rather happy with

the results, but I still hope to improve them. |

|

21st August 2004

If

you read about my 729J single stage coil gun (schcoil04)

I did for my school's research project, you will know about my

project mentor, A/P A. Kursheed from the National University

of Singapore (NUS). After hearing about my Tesla coil, he was

extremely interested. Since I had just completed fixing it

together in a nice base, I decided to inform him about my

Tesla coil. He wanted me to bring it down to his lab, which

was exactly what happened today. In the photo on the left, you

can see the coil in his lab. If

you read about my 729J single stage coil gun (schcoil04)

I did for my school's research project, you will know about my

project mentor, A/P A. Kursheed from the National University

of Singapore (NUS). After hearing about my Tesla coil, he was

extremely interested. Since I had just completed fixing it

together in a nice base, I decided to inform him about my

Tesla coil. He wanted me to bring it down to his lab, which

was exactly what happened today. In the photo on the left, you

can see the coil in his lab.

There

were some really large and well built Whimshurst generators

(motorized), with very good performance. There was also a

commercially made tesla coil at the lab. Notice how tall the

secondary is. The wire used to wind it was really thick.

Although the construction was rather good, performance was

actually worse than my own coil! The last photo shows the Mica

transmitting capacitors with a multiple tungsten static gap.

My mentor was very pleased with the performance of my coil,

and he wanted to keep the coil for maybe a few weeks to show

his students. I will collect it back soon. He might also want

me to talk and advise his students on this area. There

were some really large and well built Whimshurst generators

(motorized), with very good performance. There was also a

commercially made tesla coil at the lab. Notice how tall the

secondary is. The wire used to wind it was really thick.

Although the construction was rather good, performance was

actually worse than my own coil! The last photo shows the Mica

transmitting capacitors with a multiple tungsten static gap.

My mentor was very pleased with the performance of my coil,

and he wanted to keep the coil for maybe a few weeks to show

his students. I will collect it back soon. He might also want

me to talk and advise his students on this area. |

Gao Guangyan

Extremely dangerous: Do not try at home.

I am not responsible for anything that happens should you attempt

such a project.

Last updated: 12 Aug 2004/ 28 July 2004 |