7W of 450nm Blue Laser Light

|

Project 450 - Building a High Power 7W NUBM44-V2 Blue Laser

Introduction

It has been several years since I last worked on any laser-related

projects. The first such project I worked on was back in 2006, where I

extracted a red 650nm laser diode from a DVD burner, resulting in a

Red Laser with about 200mW output. A few years later, I built a similar one

using a 405nm diode from a PHR803t module (used for Blu-ray discs),

resulting in a ~90mW Violet Laser. More recently in 2010, I put together

a really powerful one with a 445nm blue diode from a laser projector, this time

with the diode driven

at 1A and capable of about 1W of lasing output.

Safety Notice & Disclaimer

This project

involves dangerous laser devices which will cause serious injury

if misused or used improperly. If you proceed reading, you are

legally responsibly for any use of information on this page, and

any injury caused to yourself or anyone else resulting from the

use of information here. You also agree to treat the information

provided here with respect and responsibility. This page does

not advocate the use of these kinds of lasers at these power

levels since they are extremely dangerous and any mistake will

lead to irreversible eye damage or worse. Details provided in

this project page are meant as an educational engineering

resource. Laser goggles are always used (in this case a proper

5+OD for the wavelength goggles are always worn whenever

operated). |

Over the past (almost decade!), there has been great advances in LED and

laser technology, with blue laser diodes seeing large commercial use in

consumer and industrial projectors and small desktop laser-etchers. This

has driven the cost of these diodes down, and improved power density.

What is Project 450?

Project 450 is a compact, simple, fully-integrated, constant-current

driver platform for LDs (Laser Diodes) and LEDs (Light Emitting Diodes). This

project page focuses specifically on the design and development of the

drive electronics in order to safely drive a constant-current load (such

as this diode, or any LED for that matter), and is therefore applicable

to all sorts of similar projects. The number 450 refers to the

wavelength of the candidate diode.

In this project, I develop a compact constant-current synchronous-buck

battery-powered driver capable of driving a constant current load of up

to 12A with a total power of up to 50W. This driver is adapted for driving a specific TO-5 (9mm,

sometimes mistakenly called TO-9) package 450nm laser diode at 4500mA, achieving 7

Watts of lasing output (from about 21W power input). This page focuses on the design and development

of the main drive electronics in order to safely drive this diode.

In this page,

I'll describe the engineering decisions and process for developing this driver. Hopefully this

will also be a useful resource for many like-minded hobbyists around the

world who are also fascinated by LEDs, LDs, and power electronics.

The Project 450 design including schematics, layout, firmware, and

architecture are available on this page under the

Creative

Commons License. In this page,

I'll describe the engineering decisions and process for developing this driver. Hopefully this

will also be a useful resource for many like-minded hobbyists around the

world who are also fascinated by LEDs, LDs, and power electronics.

The Project 450 design including schematics, layout, firmware, and

architecture are available on this page under the

Creative

Commons License.

Project Status

July 2019 - Some improvements: new batteries, and a

higher quality machined aluminium diode block to replace the

'red-copper' diode block. Project complete!

June 2019 - The project is officially completed and fully functioning.

Laser diode has been installed and verified with a 4500mA drive current,

21W power input.

01 Oct 2018

Optical Considerations

The heart of Project 450 is the laser diode.

The project came about due to the availability of some specific high-power laser diodes

which have emerged over the past years since my previous projects. Here we'll take a quick look at some

common diodes available today (as of end 2018), and how we arrive at our final candidate

laser diode.

Choice of Laser Diode: NUBM44-V2

In all of my previous builds, the laser diodes used

came in a TO-18 package, which is a 5.4mm diameter metal case

package (commonly also used in transistors, but the laser diode package

often has a thicker metal base for heat-sinking).

TO38, TO18 and TO5 laser diode packages showing their different relative sizes

(image retrieved from

here).

As we increase in power levels, the size of the diode

and package increases due to heat dissipation requirements. The diodes

we will discuss below are some of the popular diodes that

have came on the market since my previous project, and we will be

looking exclusively at those in a large TO5 9mm package, as well as

comparing it with my previous Project 445 build using the 'A140' TO18 diode.

2W M140 445nm TO18 (DTR)

- 2010

The A140 and M140 are 445nm TO-18 blue laser diodes which

appeared around the market around 2010 or so, in consumer projectors.

There was complicated event which occurred during that time with a

certain projector and electronics manufacturer, and as a result, the

related manufacturer and their products are not named. Therefore these

diodes are referred to as the 140-series diodes. The A140 diodes first

appeared, followed by the M140 diodes a few years later. To make things

more complicated, there are also several variants of the M140 diode,

described on DTR's page.

Beautiful close-up image of the die and different bond wires of the A140

(3 wires) vs M140 laser diode (4 wires), retrieved from

DTR's page.

In short, the A140 diodes while very good, are not as

powerful as the M140 diodes. They can be distinguished by a spot printed

on top of the tiny QR code on the bottom of the TO-18 can (where the

A140 diodes do not have it). Regardless, for their time, the A140 diodes

caused quite a stir, being easily capable of 1W output. The differences

between these diodes are discussed on the LPF forums

here.

The M140 diodes brought that up a notch achieving about 2W

output at 1.8A using a G-1/2 lens (as tested by DTR), which is the

maximum suggested running current. To keep things in perspective, in my

previous Project 445 build, I drove a A140 diode around 1050mA via a

LM317 linear regulator and 3 CR123/16340 batteries, for a total of 1W

lasing

output.

4W Nicha NDB7A75 445nm (DTR)

- 2013

This diode appeared on the market some-when around 2013,

and had a datasheet rating of 3.5W output at 448nm (typ) at I_fwd of

2.3A. When it first came on the market, it stirred up a

big interest among hobbyists since it had almost twice the rated

power as the previous popular NDB7875 diode. DTR from LPF conducted an

array of tests on this diode and concluded that it ran at 3.5A

(4.80W) comfortably, and even 4A (5.22W).

This is one of the few high power diodes of which the

actual part number is known and the basic

datasheet is available. The diode has a typical threshold lasing

current of 270 (200-350)mA, producing 1.7 (1.5-2) W/A, and a beam

pointing accuracy of +-3deg.

6W NUBM44-71 / NUBM47T / NUBM44-V1 450nm (DTR)

- 2015~

This diode (both this V1 and the V2 below) appeared on the market in

middle of the 2010s. Similar to previous diodes, they were harvested

from commercial projectors. When these diodes first appeared, they again

caused quite the stir among the laser community for their much improved

output compared to the NDB7A75.

Beam profile comparing the NDB7A75 with the NUBM44-V1, taken by DTR on

LPF

The reason for the unusual name comes not from their

part number (which is unknown, but known to be produced likely by

Nichia), but rather the number printed on the laser diode array assembly

they come in, in this case, NUBM44-71. After a fair bit of testing, it

was determined that those trays labeled with NUBM47T were likely

carrying identical diodes, and thus they have been classified as the

same.

The NUBM44-71s come in a 8-bay block, and appear to have

a higher wavelength of about 450nm instead of the previous 445nm diodes. With

extensive testing on the forums, it's been determined that the diode

does very well up to 4.5 to 5A of current drive, capable of 7W of output

power.

7W NUBM44-81 / NUBM47-A1 / NUBM44-V2 450nm (LPF

&

LPF &

DTR)

Close-up of the die of the NUBM44-V2 taken by

ABarnett

The NUBM44-81 or 47-A1s, unlike the V1s, come in a

10-bay block. While almost essentially similar, they appear to be

slightly more efficient. It has been guessed that

these diodes are likely identical to the 44-71 diodes, just higher

binned. According to tests by DTR, they seem to be about 10% more

efficient.

Above shows an array of 10 9mm TO5 laser diodes - the bare diodes are

difficult to buy in small quantities to consumers. Instead, they are

often

carefully 'harvested' from high power projector modules. The diodes are

heat-sunk into the frame, and often come in 8x or 10x arrays. Image from

here.

In order to make the distinction clearer, the community

often refers to them as NUBM44-V1 versus V2. The V2s easily push past 8W

in tests, with Alex Barnett acheiving some

10.39W at

5.4A/5V after freezing the diode.

9mm TO-5 Package drawing for NUBM44-V2 Laser Diode, note Cathode and

Anode positions. Image from generic TO-5 datasheet from

here.

The choice is clear then - we'll pick the most powerful diode available,

the NUBM44-V2. Above we can see the size specifications of the diode,

and pin 1 here is the Cathode of the diode.

Being less than enthusiastic about

extracting my own diode from a heat-sunk array, I was able to source one

online for $74.95. Above shows two photographs of the diode. In the top,

you can make out the actual diode mounted on the heatsink through the

window of the TO-5 can, and the bond wires to the diode. The bottom

shows what appears to be a QR code.

Drive Characteristics

I decided to compare the M140 diode with the NDB7A75 and

NUBM44-V1 diodes (with the V2 given a 10% increase over the V2 since I

could find no hard data). The results are presented in the chart below.

Chart showing power output and forward voltage of 3 diodes (+1 assumed

to be 10% more efficient) against forward current; data by DTR.

I created the above graph (many thanks and all credit for the data

goes to DTR for his hard work characterizing the different laser diodes),

and this

shows some interesting trends, and allows us to determine the operational

characteristics of our NUBM44-V2 diode. For one, looking at the V_fwd,

we can see that for a fixed forward current, the forward voltage of the

diode is dropping as technology improves, from the M140 diode to the

NUBM44.

Next, we see that the M140 begins lasing as low as 100mA

with 22mW output, as compared to the NDB7A75 starting at 300mA (97mW, in

line with the 270mA datasheet threshold), and the NUBM44 starting at

400mA (with about 90mW output). DTR has run the NUBM44-V1 at 5.5A for a

whole 2 minutes with no drop in output power, suggesting that the diode

is in fact capable of more than 7W, or even 8W.

We now have the following (admittedly arbitrary) operational levels for

driving the diode:

- Threshold - <100mW (400mA at 3.4V)

- Bright - 500mW (600mA at 3.6V)

- Powerful - 2000mW (1350mA at 3.9V)

- Turbo - 7000mW (4.2 to 4.6A (4.5A) at 4.7V)

We will use these values when configuring the driver.

Optics

For best optical power output, a single element G2 lens is used.

I purchased this from barnett_unlimited on

eBay

for $14.95.

This lens features a M9x0.5 thread for standard 12mm modules

(as well as the diode block I will be using), and has an AR coating for

405nm - 520nm. Front and back focus are quoted as 4.02 and 4.8mm,

transmission of 98%, 2.357mm working focus, L-BAL35 glass type, and is

best suited for engraving.

A 2 or 3 element glass lens will be better suited for

longer distances though.

Another great option is the 'DTR-G8-Collimating Lens",

offered by

DTR. As described by him, "this lens is a long focal length single

element glass lens with a broadband 400-700nm AR coating. It has a 90%

pas efficiency which is amazing for a longer focal length lens. It does

an amazing job of cleaning up optical aberrations around the projected

spot caused by stray light reflecting off the edge of the emitter or in

the lens barrel. This what is seen as box shape that is projected under

the spot created on single element lenses with the newer very high power

diodes. It creates a greatly reduced spot size while maintaining a 90%

pass efficiency compared to the 96% pass efficiency of a DTR-G-2."

Thermal Considerations

For the thermal assembly I opted for a red-copper diode

block.

I was able was able to get this product from techhood on

eBay

for $10.35 which included a standard 405-470nm AR coated glass lens

(MP905x8mm). The 13x12x15mm copper block allows a press-fit for the

TO5-9mm diode, and has two mounting screws on the bottom. This included

lens will do well for standard usage, at the cost of reduced power

output due to losses in the optics (which will be upgraded to the ones

described above).

This copper diode block as well as the main PCB will be

mounted on a 5mm thick aluminium plate, which will act as the

superstructure, as well as the main heatsink for the entire device.

Since there is no plan to run the laser continuously for more than 10s

of seconds at a time, this design will work just fine with no danger of

thermal overload.

Electronics Design

Laser diodes are similar to regular LEDs in a few

aspects. First, there is a starting lasing threshold - a threshold voltage for

LEDs, and a threshold lasing current for Laser Diodes (LDs). Second,

these diodes have a fairly steep IV curve - once the threshold operating

point is reached, a small increase in voltage results in a

disproportionally large increase in current. Furthermore, this

characteristic fluctuates greatly not only with operating conditions

(such as temperature), but also varies from die to die. Finally, these

diodes have a negative temperature coefficient - an increase in

temperature leads to a drop in forward voltage, and therefore a rise in

current. As a result, when driven from a constant voltage source, LEDs

and LDs can quickly overheat, enter a dangerous positive feedback cycle,

leading to thermal runaway and ultimate destruction of the diode.

Using a resistor is common way of limiting current to

LEDs, and can also be used for LDs. Resistors however are inefficient,

especially as power levels increase. Therefore the sensible way to drive

high power LEDs and LDs are carefully designed regulated constant-current drivers.

Linear constant current drivers as used in my previous

projects act essentially as 'adjustable

resistors', and power is dissipated in a pass transistor (acting as the

'resistor'), but have additional functionality over simple resistors but

allowing adjustable current

control.

To improve efficiency, a switching DC-DC converter can

be used instead. A feedback loop senses the forward current, and then adjusts the output voltage

of the DC-DC converter accordingly to maintain that current. It is

possible and in fact easy to design DC-DC converters with over 90%

efficiency, so this approach is significantly more efficient than a

linear driver, at the added cost of complexity. This will be the

approach we will be taking.

Having had some experience with my recent flashlight LED

Driver projects (such as the GXB172 50W

flashlight driver), we will

now apply the same ideas and learnings for this project. Before we

begin, let's take a look at some of the popular switching

constant-current regulated drivers used by hobbyists today (at time of

writing). Most of these are buck-type step-down drivers, taking power

from an array of lithium batteries (typically 2S or more), or an external

power supply.

What Drivers are Available Today?Super X-Drive

5.5A - $26

The Super X-Drive (SXD)

V3 )

V3 is a 10.3 x 15.4mm buck driver by Lazeerer. It's available on eBay or

on DTRs shop for $26. It features adjustable current control via a 5V

1kHz PWM modulation (or simply a resistor), with an absolute maximum of

12V input. It has a listed 1.6V threshold for enable, maximum of 5.5A

output. The main switching converter is a 8-SOIC part, and based on the

specs listed, is very likely a Texas Instruments

TPS54628 or one of its variants - a simple 4.5 - 18V 6A synchronous buck

converter IC with integrated 36mR and 28mR FETs.

ACS5500BU 5.5A Driver - $29

The

ACS5500BU Rev 2 driver sold by x-wossee on

eBay and

DTR is a 10 x 16mm driver in a form factor and layout which I can

appreciate (looks well designed). It is available for $29, and replaces its predecessors - the BlackBuck 3 and 6. The board has a very compact and single-sided layout

(allowing for easy heat-sinking), features a 'high-side' design,

soft-start, ceramic fuse, and sensible output and input pads. The supply

voltage is rated 6 - 14V, load 1.5 - 6V, 250ms SS, 140C thermal limit,

and 5.8A output. Current adjustment is done via an on-board trimmer

resistor, and the board features a 5V-tolerant enable pin. The sense

resistor appears to be a 10mR resistor with some sort of SC70 op-amp as

the current sense amplifier or similar for CC regulator.

Based on the description and unusual physical

characteristics, it's pretty easy to guess that the main switching IC is

the nice Richtek

RT7298B HGQW, a 3.5 x 3.5 14 QFN 6A 18V synchronous buck converter,

featuring 26/19mR internal FETs, adjustable soft-start ($3.09 in 1x qnty

on Digikey). One feature I like about the ACS5500BU is that it has

exposed ground pads on the bottom, allow good heat conduction with a

heatsink. The ACS4500BU is a similar driver ($29) and is essentially the

same, but with a slightly lower profile (likely smaller inductor), and

1A lower power handling capability.

BlackBuck 8M Rev 3 8A Driver

The BlackBuck 8M Rev 3 sold by x-wossee on

eBay and

DTR for $39 is the larger cousin of the ACS5500BU. It shares a layout and design, but improves on its power handling

capabilities. The 8M takes in 7 to 12V, with an output of 1 to 8A, 100us

rise time, 0.5ms startup delay, includes pads for external current

control via 5V PWM or a potentiometer, has an on-board trimmer, and also

has temperature cut-off via an external 3950/10K NTC (or can be uses as

an interlock, short to disable), all on a compact 17x16mm PCB.

Based on the description and the fact that the boards

has a 5V reference output, the BlackBuck almost certainly uses the

International Rectifier

IR3475 10A integrated SupIRBuck regulator ($3.58 on Digikey in 1x

qnty). This 4x5mm 17 QFN features 3V-27V input, 0.5-12V output, 10A load

capability and 23/13mR internal FETs. The SOT23-5 device on the board is

likely a 5V regulator (hence the 7V minimum input, and this powers the

VCC rail of the IR3475), and the SC70-5 package is likely some sort of

amplifier for current sense.

With the above as an inspiration, let's see if we can do

one better without spending too much money.

Synchronous Buck Design - TPS56C215

When designing the driver for this project, I was

initially thinking of using the Texas Instruments

TPS565208

buck converter ($2.14 in 1x).

TPS565208 reference design from TI's datasheet of this IC

It is super simple and easy to use and set

up, has a good 4.5-17V input, and is capable of 5A output with 31/16mR

internal FETs. This will be sufficient to power our laser diode

(at 4.5A). It also comes in a cute and friendly SOT23 package. However,

why stop at 5A when we can go all the way to 40A? The Texas Instruments

TPS548D21 is a 1.5 to 16V in 40A converter and

still comes in a small 7x5mm 40QFN package, including 2.9/1.2mR power

FETs! However at $10.89 per piece (at 1x qnty on Digikey), it is

definitely excessive in every sense of the word.

Suggested layout of the TPS56C215, from TI's datasheet of this IC

Sensibility got the better of me and I eventually

settled on the

TPS56C215RNNR ($4.56) 3.8-V to 17-V Input , 12-A Synchronous

Step-Down converter. Being TI's smallest monolithic 12A IC, it measures

just 3.5 x 3.5mm, and comes in a well designed VQFN 18 'hot-rod'

package. This design allows for a very clean and compact layout as shown

above, as well as having excellent thermal properties. The TPS56C215

features integrated 13.5 / 4.5mR FETs, 0.6 to 5.5V output, 4.5Vmin start-up

without external bias, optional external bias for improved efficiency

and an adjustable soft-start. Its 12A current capability means that

it's good for some 50% more power handling capability than the

BlackBuck8, while being more efficient (better FETs), and more compact.

This shall be our sensible IC of choice. Next time we

build a bigger one :-).

Requirements

The requirements for this design can be summarized as

follows:

- Input: two CR123A / 16340 lithium batteries, 6Vmin to

8.6Vmax input

- Output: 100mA? (depends on threshold lasing current) to 6000mA

We will design for 5.5A max output for now for the safety of our NUBM

diode, but this design will easily allow us to go to 12A --> 50W of

power!)

- True constant current regulation

- ~250ms s- ~250ms soft-start

- 3.4V to 5V output

With the requirements in mind, we can begin our design.

Fortunately, TI has an excellent

online tool to help us with our design. It works really well, so

hats off to the engineers who developed the tool. I started a design

with 6-8.6V input, 5V at 6A output, 30C parameters, and generated a

reference design.

Switching Regulator WEBENCH Power Designer

Using the online tool, we quickly generate our design.

The design suggests one of my favourite inductors as the main buck

inductor, being the Coilcraft XAL7030 series in 3.3uH flavour, having a

DC resistance of 19.5mR and an I_sat of 12.3A. For even better

performance, we can switch to the XAL7070 series which will improve

efficiency even more by dropping the DC resistance to 8.56mR (I_sat of

19.4A), at the cost of increased size.

Efficiency and power dissipation simulation using TI's Webench with the

parameters described.

With the 7030 inductor, the results are pretty good,

with a design capable of >95% efficiency throughout most of the range.

Inductor power dissipation is a maximum of 706mW with 1.57A peak ripple.

IC power dissipation is calculated to be about 955mW for a total of

1.66W dissipated including passive losses. Switching to the XAL7070

drops inductor losses to 311mW, resulting in a total 1.27W power

dissipation.

The generated design calls for light load operation of

FCCM (instead of DCM, to maintain a constant switching frequency) and

current limit of ILIM (vs ILIM-1) and a switching frequency of 400kHz.

For the SS pin, the equation for calculating is C_ss = (T_ss * I_ss) /

V_ref, where I_ss = 6uA and V_ref = 0.6. Given a 200ms desired ramp,

C_ss = 2uF. The recommended output capacitor is 88uF, and 40uF for the

input side, with equal caps on each side of the IC.

Here are some additional layout guidelines:

• Recommend having equal caps on each side of the IC.

Place them right across VIN as close as possible.

• Inner layer 1 will be ground with the PGND to AGND net tie

• Inner layer2 has VIN copper pour that has vias to the top layer VIN.

Place multiple vias under the device near VIN and PGND and near input

capacitors to reduce parasitic inductance and improve thermal

performance

• Bottom later is GND with the BOOT trace routing. Feedback should be referenced to the quite AGND and routed away from

the switch node.

• VIN trace must be wide to reduce the trace impedance.

Finally, the entire system will be controlled by a small

Atmel ATTiny microcontroller. This MCU will handle the different current

modes, as well as display useful information such as battery status,

power setting, and so on.

Battery Choice

The choice of battery size is the CR123-size, which is

typically non-rechargeable; or alternatively known as 16340, which is

the rechargeable variant. This size was chosen for its compact

dimensions, and mostly because I had a bunch of Lithium CR123 cells

lying around, as well as several EBL-branded 16340 cells. At the

expected load of just over 20W, the expected cell current (two in

series) should be between 2.5 to 3A.

Picture of the white INR16340 cells from Vapcell, image from Vapcell's

website.

The red EBL-branded cells handle 3A with no issues, but

the current best 16340 cells I can find on the market at time of writing

at the

Vapcell INR16340 (white) cells. These have a rated capacity of

800mAh, and are rated 7A discharge, and as measured by HKJ, are

currently one of the best 16340 cells at time of writing.

In fact, comparing with larger 18350 cells, they

certainly hold their own at high discharge currents. While the target

diode only requires 20W drive at this time, the driver is technically

good for up to 50W, so it will be nice to have the option of future

upgrades.

For the record, at time of writing (early 2019), the

best performing 18350 cells are:

-

Shockli 18350 1150mAh Black

-

Vapcell INR18350 1100mAh Purple

-

Keeppower 18350 1200mAh UH1835P Black

Peripherals - USB Charging

I wanted to add an additional micro-USB charging

capability to the project for ease of charging the batteries. The

batteries I plan to be using are two 16340 lithium cells in series with

a maximum charge voltage of 8.4V for both of them in series. The goal

was a

charge time of about 1hr. 16340-sized batteries typically come in about

700mAh capacities, so the target charge current will be 700mA.

Automagically generated design using TI's Webench Power Designer using

the LMR62421 Simple Switcher.

We get an excuse to use a super cute 4020 inductor

from Coilcraft as the boost inductor!

The first step calls for the TI

LMR62421 Simple

Switcher 2.7V to 5.5V, 24Vout, 2.1A Boost Converter in SOT-23, boosting

5V from USB, to 9V. While not the most efficient (since it is

asynchronous), it's simple and easy to implement, with a simulated

efficiency of >88% at 700mA output. This 9V rail feeds into a TI

BQ2057W Low Dropout

Linear 2-cell Li-Ion Charge Controller with a PFET pass element for

linear charging. A safety interlock with the Atmel MCU prevents turning

on the laser diode if charging is in progress. The PFET will be the main dissipative element during

battery charging.

Next, the design. We first determine the maximum power dissipation in

the transistor. The worst case happens when the batteries are fully

depleted at 3V each, the charge current is at maximum of 700mA, and

input voltage is at its maximum 9V. Then power dissipated = (9V - 0.125V

- 6V) x 0.7A = 2.0125W. 0.125V is the voltage dropped across the current

sense resistor.

The minimum theta_junction_to_case can then be calculated using

the maximum junction temperature (usually 150C), the ambient temperature

(usually 40C) and the power dissipation. Hence theta_jc = (150 - 40) / 2

= 55C/W. We will find a package that has a lower theta.

Next we calculate the required gate threshold using V_gs

= (0.125 + 1.5) - 9 = -7.375V. Here 0.125V is the voltage drop from the

current sense resistor and 1.5V is the CC pin output low spec of the

BQ2057. Any PFET with a V_gs within -7.375V will work (should should be

plenty). For current handling capability, we simply give us a 2x buffer

at >1.4A. Finally, any device with greater V_ds than 10V will work fine.

After a parametric search for parts with VDS <= -20V,

theta_JC <= 55C/W, I_D >= 1.4A and V_GSth >= -7.375, I chose the

SI7615CDN for it's impressive -20V 35A capability, and outstanding

junction to case of 2.9C/W, an order of magnitude better than SO8

packages despite its much smaller size.

SchematicThe follow is the schematic for Project

450 for reference.

The schematic will be updated here soon. Please check

back frequently!

The Project 450 design including schematics, layout, firmware,

The Project 450 design including schematics, layout, firmware,

and architecture are available from this website under the

Creative Commons License.

Layout

With the electrical design done, it was time to do the

layout.

The layout was constrained to fit on a 100x50mm board

outline, whose size was dictated by the battery holders. Layout was

fairly straightforward due to the large amount of space on the board.

Above we can see a render of the completed layout.

The

left side consists of the 9V boost regulator, as well as charging

circuitry. The right side consists of the constant current buck

regulator, and a ATtiny microcontroller sits in the middle. The

microcontroller handles the entire system for various kinds of events.

Here are a few features:

- Security Safety interlock requiring secret code to

be entered via switches before system unlocks, impossible to turn on in

a bag

- Constant current control with 4 programmable constant current power

modes

- Battery monitoring and low voltage cut-off

- Charge management

- Error codes via a total of 5 colourful LEDs

Thermal handling was also incorporated into the design.

To heat-sink the switching regulators and the battery

charger, the entire PCB only has components on one-side, with exposed

ground pads on the bottom as can be seen above. The PCB is screwed onto

a milled aluminium baseplate, whereby the exposed ground pads allow

thermal connection to the baseplate.

To prevent shorts, holes are milled into the baseplate

for through-hole legs to sit in. A kapton sheet was then laser-cut to

insulate all other parts, and thermal paste was then applied to the

exposed ground copper pads to interface with the baseplate. A cutout in

the PCB allows the diode, housed in a solid copper mount, to be attached

directly to the baseplate.

Assembling the PCB

The PCB was fabricated to be 1.0mm thick. Once they

arrived, I was able to quickly get the board soldered up. In addition, a

piece of 5mm thick 6061 aluminium stock was cut to 50 x 100mm size, and

carefully milled, drill and tapped to accept 8 mounting threaded holes,

and several more milled cutouts for through-hole components.

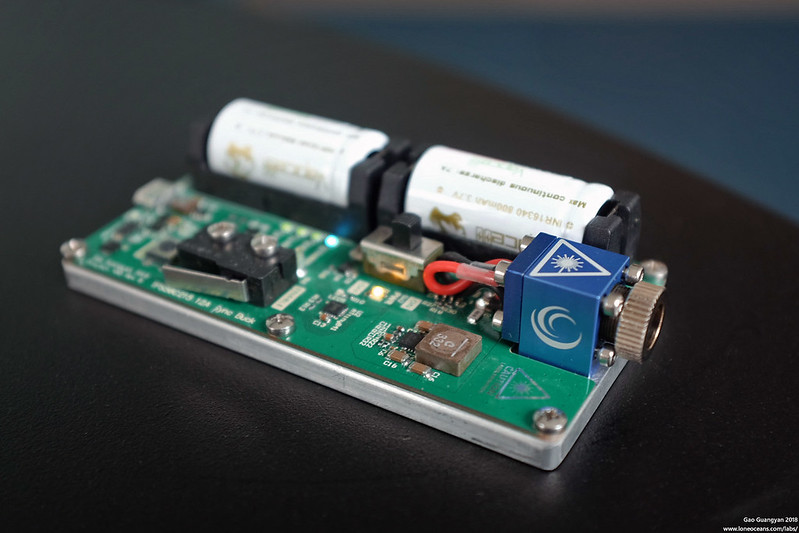

Above shows the result of the completed and assembled

board with all components installed. It's nice when the project finally

comes together and looks exactly as envisioned! A few small errors in

the first revision led to an updated Rev B PCB, with all functions

tested to be working with no further errors.

Above shows the completed project with EBL-16340

batteries, and with all 6 LEDs illuminated (4 cyan mode LEDs, one warm

white power LED and one orange debug LED). In addition, a red and green

LED indicate charging status when a USB cable is plugged in (for battery

charging).

July 2019

Tweaks and Improvements

Here's

a quick update since the completion of the project. I've since updated this build with an improved diode

host.

Project 450 now uses a very well machined aluminium diode block made by

Lasertack from Germany. Thermal performance is in fact much improved,

since there were concerns about the (relatively low) quality of the 'red

copper' material used in the original diode block.

In addition, I've upgraded the batteries used in the project.

The red 'EBL-brand' cells have been swapped out for some of the best 16340 cells commonly

available - the white Vapcell NR16340s (see the test here by

HKJ). They

were verified to have absolutely no trouble supplying the ~20W required

in this build. This marks the completion of this build and I'm quite

happy with how this came out.

Results

Jun 2019

Project 450 - first light & comparison with 1W A140 build

Above shows Project 450 in action! In this photo, notice

the power level is set to 'Medium level', or a 500mW output. In order to

make the beam more visible, some water droplets were sprayed.

More photographs of higher quality to come soon! The

driver was tested together with the NUBM44-V2 diode all the way up to

the 4500mA operating current, with excellent results.

More to come soon - please check back frequently!

Useful Links

Community References

DTR NUBM44 - DTR's page on this laser diode and associated

BLF page

DTR 8A BlackBuckM - a small 8A Buck converter for laser

drive

NUBM44-V2 - LPF page on this diode

Barnett_Unlimited - is 'not a scammer'!

EE Components and Datasheets

Digikey - DC-DC Switching Regulators

MPS - MPS DC-DC Switching Regulators

MIC24056 - Micrel 12V 12A Buck Converter 5x6mm

TPS54821 -

TI 17Vin 8A Sync Buck 26/19mR 3.5x3.5mm QFN14

TPS568215/OA - TI 17V 8A Sync Buck 19/9mR

3.5x3.5mm QFN18 DCap3

TPS53318 - TI 25V 8A

Sync Buck 5x6mm

TPSM84824 - 17V 8A

Buck Power Module in 7.5mm2 Footprint with Inductor

IR3841MPbF - IR 16V 8A Sync Buck 17/9mR 5x6mm

MP877x - 17V 10A Sync Buck 17/8mR 3x3mm

MP2639A - MPS 2S USB Battery Charger

NDB7A75 - Nichia 3A 450nm Laser Diode Datasheet and

LPF discussion

Digikey - Slide Power Switches

LM317L - 100mA

SOT89 CC Regulator

Designing a CC Buck Converter - TI Application note

Back to main page

(c) Gao Guangyan 2026

Contact: loneoceans [at] gmail [dot] com |